Forum Replies Created

- AuthorPosts

-

Okay, I think the problem is mechanical. I’ve setup the system in such a way that the power is all external. When I press play the left reel spins but the right one does not (see image). This would put undue stress on the lowly BC547 causing it to burn. Likely as a protection for the BD435.

Now my question is: how the hell do I dismantle this deck? Is there anything in the way of a ‘tutorial’? It doesn’t seem to be all that easy and mucking around in B&O decks is a sure way to never having a working deck again.

Many thanks!

BB

Okay check, no problem. I’ll start with injecting about 2v as I would see a current draw far above what is reasonable already. Can always ramp up the voltage a bit at a time.

Thanks!

BB

TR9 (BD435) is fine. So it seems that the TR17 is where the problem ends. I need to think about this because I just can’t find anything wrong. Desoldered all transistors in the pathways to be sure, they all test fine. F32 transistors also all fine. No shorts. So why this transistor blows in such a simple circuit when not even full power is applied is a mystery at the moment.

Suggestions are very much welcome 🙂

BB

Hmmm. TR9 which is connected to TR17 was also busted. On replacing the transistor it immediately blew when power was applied (through a variac). There appears to be a short somewhere, I need to check if TR17 survived this. The power supply before the fuse is fine, all voltages are good if C12 (2200uF) was bad it would have killed the 12v power regulator as well (but it is fine).

So it has to be something downstream. The motor is good, I can apply just 4v DC and it spins without a hitch. I can move the two reel tables (I think that’s what they are called) by hand, no issues. There is a small motor on the backside of the tape assembly, this also works fine.

I have checked all of the transistors in the chain leading to the motor in the schematics and can’t find anything out of the ordinary. Only near the power supply are 2 blown transistors of which one blows immediately after replacement.

I need to think about what the hell is happening here. Cascade like this is not normal.

Bert

sorry it is very busy over here. TR17 was busted, replaced it with one from stock but that did not solve the issue. I need to analyse this further as it seems there has been a cascade somehow. That BD435 would not blow quickly at all.

- The voltage regulator (IC3) is good.

- The 2200uF cap is also good.

- F2 fuse is good

Need to trace the entire path again even though I did not find any that were clearly broken.

Bert

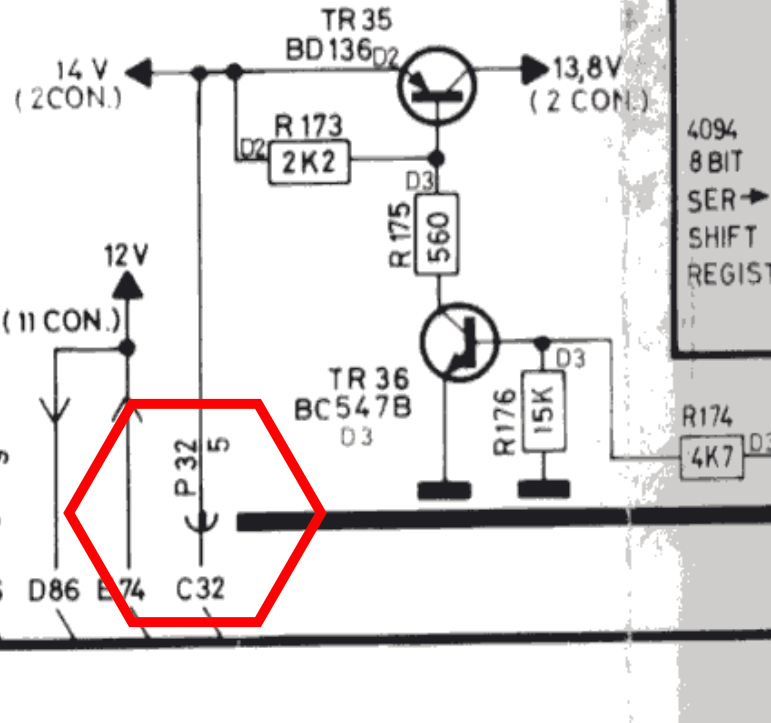

I tried tracing the 13.8v line. In the end it comes to a connector which is called C32 in the schematics. Sadly that line can’t be found anywhere in the schema. I really, personally, hate B&O schematics. They are always so damn faultridden and overcomplicated. That said I expect that line to lead to a voltage regulator or something that is busted because there is 6v on the input line. Not 14v as the schematics show. Now where to find that doohickey……

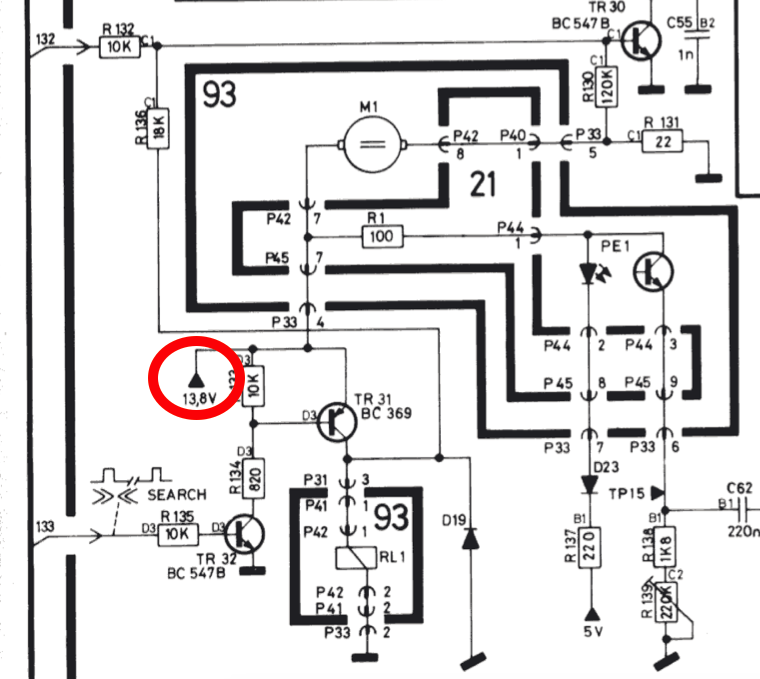

Hmmm. The main motor should get 13.8v when engaged but is getting 0v.

As is usual with these B&O schematics I can’t find where this 13.8v is coming from. It just magically appears in the schematics (see the red circle).

BB

Good morning Martin,

Yes the burning resistor is indicative of a larger issue. I replaced the resistor with a 250mW metal film resistor, it should be fine. The rest of the mechanism is all ok, nothing seized and has a new Beoparts belt. It is a one belt drive. It was playing fine when suddenly it slowed down pretty fast and then stopped altogether. This coincides with the burning resistor.

But. It seems there is no power going into the drive. The motors in there are fine, I can turn them on external power, nothing is seized. This must be the reason why the drive isn’t spinning. At least the capstan motor isn’t getting any juice at all. I expect the other motor to be down as well (I’d rather not muck around with that one even on low external voltage because it drives a lot of gears.

I need to check these B&O schematics on where the power to the motors is actually coming from and if there are any dependencies on that.

Bert

Hi Christian,

replaced the resistor but unfortunately no success. When I load the tape the array comes up and then flips itself (direction change) and then disengages. It never starts to run. Fast forward and reverse are fine so it’s not the new belt.

Something must have bitten the bullet when the resistor died in flames. Oddly I can’t find any transistors that are dead in the water in the circuit.

Bert

Hi Christian,

I’ll be damned, exactly the same resistor is burned to a crisp on mine. I’ll replace it with one that can handle a bit more power. And i’ll also put it on ‘legs’. I have a Beoparts belt which is the best I know, so i’ll put that on as well.

Let me see if this will fix the issue :-).

Bert

I’ll be damned it was indeed that relay. Changed it to another one left over from a spare parts project. Odd behavior of the relay though, a standard speaker relay (which I read this to be) would not pass audio if ‘defective’.

Oh well, you learn something new everyday. Especially with B&O machines LOL.

BB

7v is getting in at port – right – #2.

4.5v is present on the pins of the other ports (data ports I assume)

This appears to be correct.

There is no short between pins of port – right – #1

I think there is an issue with the datalink but I can’t find it in the schema.

BB

Have you checked the mute relay? This is usually the culprit when the speaker 2 outputs are working fine.

—

No I did not check this because there is audio on the speaker pin. I would expect that an issue with the muting relay would prevent audio from passing to the speaker port. As far as I can see it is much earlier in the signal processing?

When I trace the audio there is a signal on the output pin of the speaker port. This signal dissapears when I attach a load (speaker) to the port. I can’t see any damage on the port, there are no shorts on the pins. Voltage of 4.5v on the pin for the dataline seems correct.

Hi all, Christian,

i’ve ordered the parts from Beoparts and they arrived. After an afternoon struggling with the re-assembly of the cassettte transport it is now working as it should. I compared the old and the new rubbers but aside from a bit of greyness they are identical in size and shape. I think that if you were to use ‘rubber renew’ you could easily get the same results. The tolerance appears to be very narrow, just a tiny bit too little friction will drop it off.

Now it’s off to my other three decks. Not really looking forward to doing it but after this one I think i’ve nailed the process ;-).

BB

Hi, and welcome to Beoworld

That’s indeed the usual failure on these machines. You have to renew every single idler tyre and quite possibly the broken clutch arm. You will find the correct parts (buy the main belts too, beware of eBay random ones) at Beoparts. Happy repairs!

—-

Is there any website or forum page where I can find more details? All belts have been changed with good quality ones (even purchased from Beolover). As far as I can see the Idler wheels are all in the same condition, I don’t expect it to be this. Dismantling the mechanism without knowing what you’re doing is a sure way of never getting it back together 🙁

BB

- AuthorPosts