Forum Replies Created

- AuthorPosts

- 1 June 2022 at 01:09 in reply to: Beolab 4000 – Taugen die was? Vergleich mit Beolab 6000 etc.. #34447

Und wie siehst du die 8000er im Vergleich zu den 4000ern?

I reply in English since I don’t speaker German (and I regret that!) and had to rely on that evil google trad. Anyway.

Just my two pfennigs: I have BL4000 MK1 and 8000’s MK1 phase 2 (woofers in parallels).

So far, the 4000’s wins, deep bass, clear meds, brilliant highs. “My” experience with the 8000’s (I repeat: MK1 phase 2 (woofers in parallels)) is disappointing: muddy meds, not that deep bass, average global sound.

BUT!

I’ve replaced the foam inside for better ones (mandatory as the originals will sooner or later make the speaker fail). Didn’t make a point by point comparison since then, but the 8000’s seems to sound a little better (lots of threads says ‘day and night’ but I personally didn’t experience this).

As one member pointed out, and this is what I think when you speak about B&O, there is a compromise on sound, placement, look, and obviously use. Speakers for TV are not the same as speaker for music (main) or music (background). Personally, I’ve never find any elegant solution to use BL4000 as TV speaker, when you just have to put 8000’s or 6000’s next to your black mirror to make it elegant and obviously, wild sounding.

So, in a nutshell, depending from where you start and where you want to go:

- 4000’s: very good for music, shelf placement, or along an ouverture or any 2xxx/3xxx Audiomaster.

- 8000’s (with care or chose MK2/not 8002 – MK2 have a bulged dust cap and not a cup one) for TV or music floor standing.

- 6000’s for TV if you’re on a tight budget.

- Maybe 8000’s for booth if you’re not used to whatever high end speakers you love the sound.

The magnet arrived!

Stick 6 of them in corners and middle sides.

And stick metallic “tablets” (don’t know English name…) in the same places on the fret…

Intensive testing for now but si far it holds the fret without vibrations.

One of the characters clearly liked his B&O.

Or most likely, one of the set designer!

Always!

Done, Thanks for reminding this to me.

Hi Henrik,

I’m starting to figure out I’ve got some sort of Frankenstein’s Beovox:

- Both speakers are P50, but with different serial numbers.

- One fret has P45 badge and holes for the missing pins but the other has P50 badge and no holes in the fret.

- Both speaker, as regular P50, have no holes in the front face.

Luckilly, both sound good enough for my ears and are closer enough in wood shade.

I’m waiting for neodyne magnet to try to keep the fret in place.

Thanks for trying the speaker link driver. Mine are not actually moving, more like “deforming” or “crushing” when you push them. As they seems to sound good or at least not weird, i’ll try to stop focusing on that question. This is where we miss you Dillen!

Thanks Henrik.

Wednesday!

And we have two perfectly sounding Beovox P50 panel speakers!

There are 2 different types used. A 6mm and a 19mm wide foam-tape. I use the original foam-tape used by B&O to keep the BL8000 as original as possible.

Could you tell us where you get it, and what’s the thickness for the two strips?

Thank you.

The newer version of foam has been improved compared with to the previous one. The foam sits tight around the bass pipe to prevent audible resonance at lower frequencies. The V-shape sits on top of the other parts and provides a “chamber” for the drivers.

Ok, now I feel totally stupid. I mount them wrongly because the picture wash cut at the top and I believed it was top of the speakers. I’m good to open them again.

That mount make sense.

Apologies to Geoff.

Mmmm, in white!

Please could you post a shot or tell me how the frets are attached to the front face?

Also something I did’nt find on the old forum: the page link driver doesn’t move when you touch it (like woofers do). Is it normal or are they prone to seizure too?

Thanks in advance Henrik.

Thank you Henrik,

Apparently they were made to complement the 6000 system. Do you own a pair (or more) ?

Hi Guys,

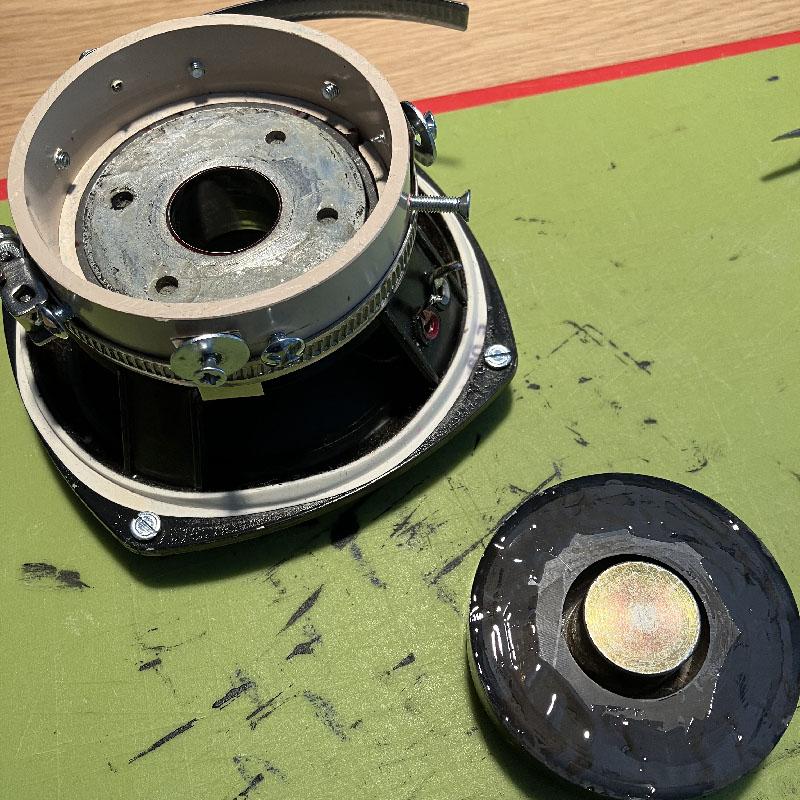

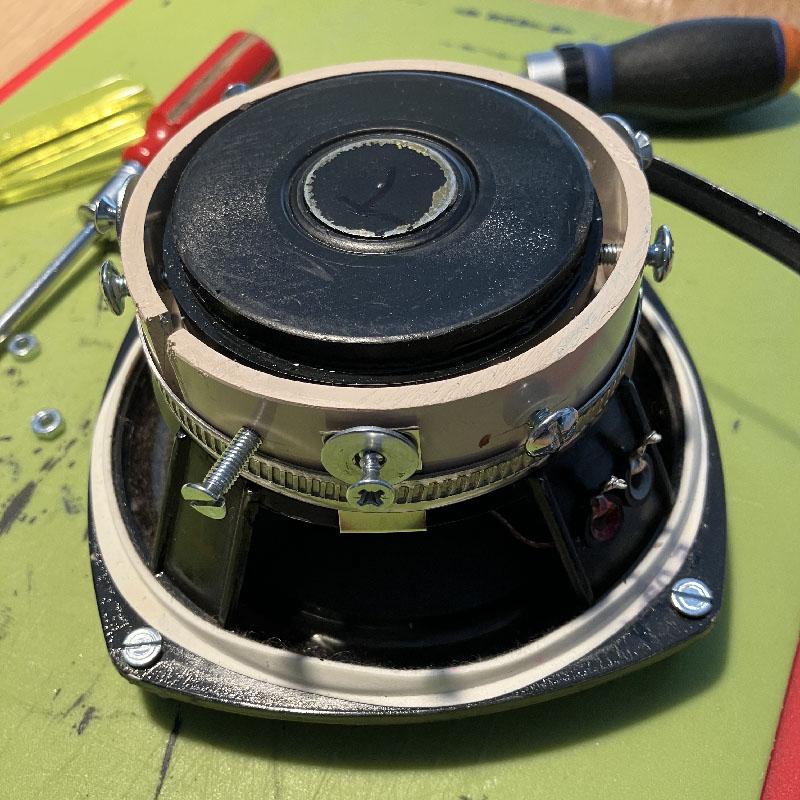

The last speaker is drying now. Actually it was a bit of a struggle. After glueing it I did notice it was still scratching slightly. Believing it was not be noticeable I let it dry and of course, it was extremely noticeable. So I had to “break” it again and it was hard, violent and painful. But warming it with and hair dryer helped me to extract the magnet without too much damages. It was very difficult to center that one but right now it’s drying and it seems to be well centered.

So here we go for the pictures:

I fitted four bolts to be able to place the speaker on a flat surface without hurting the surround.

I also blocked the cone to prevent the coil from protruding from the base.

Scratching and cleaning the old glue residue.

The base in the 10€ rig and the magnet ready for the wedding.

After a loud “clac” sound, the magnet is ready for adjustment using the 6 screws around the rig.

I had to cut the dust cap to see the magnet core and use it as reference for adjustment. Not completely to be able to glue it back. But if everything works I may offer us brand new dust caps as the glued back are not so pretty.

After roughly 15-20 min of adjustment, the coil release itself around the magnet core and you can do quite fine adjustment. The “precision” of the adjustment is given by the screw you use. Some people uses wood screw, I prefer metal bolts with flat end for better contact with the magnet.

Once the cone move freely (and without any scratching noise) you just have to let it dry.

The most scaring part is what happened with the second speaker: breaking the coil wire or damaging the coil tube made of some sort of tin sheet easy to bend or dent. Thats why it’s important to protect the coil and check for electrical continuity at every step before the magnet is in place and the glue dry to much. The rubber surrounds give a little flexibility for that.

Once it’ dry, I put a bead of glue between the magnet and the gasket base and let it dry again.

Listening session Wednesday if everything goes fine.

Cheers.

Good evening cavscout,

The Beosystem 5000 is a complex system. I never did like t until I owned one and ended u loving it.

Maybe your problem is related to a common fail of the system that is the ribbon cable between the keyboard and the system. It needs dismantling and work, but if you’re not afraid of fixing the CD50 or the BC5000 it’s nothing beyond usual abilities.

The “Big” Remote is mandatory to program the system, which was a breakthrough feature in it’s time but not so useful nowadays. For everyday use the “little” remote is more useful (volume, source…). Nevertheless, when owning an BS 5000, the MCP5000 is a very impressing thing to have and very usefull too, even if you dn’t need to program any record.

Search in the forum 2012-2022, you’ll get plenty if not all the information you need.

All the best.

Hi alls,

I’m excited and a little bit proud to announce the first panel is playing music!

It was a battle to reunite the two ends of the broken wire in the coil but I worked.To answer my own first question, this speaker is amazing and the bass are round and deep even thought I didn’t push it too far. Maybe not as clear as S45’s but very close and to be confirmed when (if) the second speaker will be repaired.

Drivers 3 and 4 are open on the table and waiting for their glue.

Also thinking to a way to fix the frets, maybe with neodyne magnets?

As it was a stressful first attempt, I didn’t take pictures but will when fixing the other speakers.

Again, thanks to Beoworld for all the useful informations it has provide.

Even if the purist part of me has some reserves, the User part of me scream it’s too good and quite well done aesthetically.

Would you share a little be more on the process to do it?

Thanks.

Hi,

The two last days where tense. After glueing and testing the first woofer it did work well.

Full on confidence and arrogance I went to the other one and I was punished for my pride.

The coil wire broke, and it was a nightmare to manage to relink it. The tool for centering the magnet broke too and I had to take some distance before coming back (24h) and start it all over again.Fortunately, the second woofer is drying right now, the contact show continuity and read close to 7 ohms of impedance. It will be mount tomorrow in the evening I hope and I hopefully will be able to listen to one speaker.

Regarding the previous question about the fret, I’ve found pictures on the net that confirm the the fabric is original. I don’t know what to do with it right now because as original I want to keep those speakers, I can’t see a way of attaching the frets without them vibrating. I’ll see when I’ll be there.

A new question arises: the Phase Link driver, it looks like stuck too, no movement at all. I wonder if it’s by design (I hope so because on my S45, it’s not moving too). And also, why is that thing sticky?

Cheers.

I believe “damiendada” is some sort of spamer because his two post are just “I agree and was asking myself the same…”

KolfMaker, nowadays the PSU are small. I dont know about the empty room size into BL6000 bt couldn’t you fit a PSU, feed from the main power socket to the voltage you need and tuck it somewhere inside the beolab? That would also makes your mod totally independent of the beolab electronics and rule out any related problem if they happen?

As another member would say… Progress!

Thank you Guy, after a little search the Beolink MCL82 type 2041 works with the BS5000 and BC7700. The search also returned a little extract from the Beoworld product page that says: “It was superseded by the later MCL2 system which used Beolink 1000 codes.”

So I’ll assume it may potentially not work with moderne remotes. When I had a full 5000 system, I used little cheap IR repeater to help the return of the IR signal to the remote. It did work when the same repeater don’t with modern Beo remotes (1000/4/6/5000). So the theory is it wont work.

To the OP, apologies for this little out of topic, I felt like it didn’t deserved a full thread on it’s own. It’s now ended.

- AuthorPosts