Forum Replies Created

- AuthorPosts

-

Sounds really sensitive problem. Maybe some grounding issue in cables, platter adjustment. I would check mechanically first, like Pepps above mentioned. Is the amp same series as the 1700 i.e. compatible. If it is generating static electricity when platter moves, maybe try to put your hand on metal part of player…any effect. You create discharge route with your body. But first I would open it up and check any physical issues.

Yeah the above photo is not showing the issue(bad photo angle). But both arms are skewed just enough to make this a problem. I understood that there is that fine tuning (showed in photos above), which I managed to adjust as far as they can be. And now the needle is just and just above the record. But it varies by records.

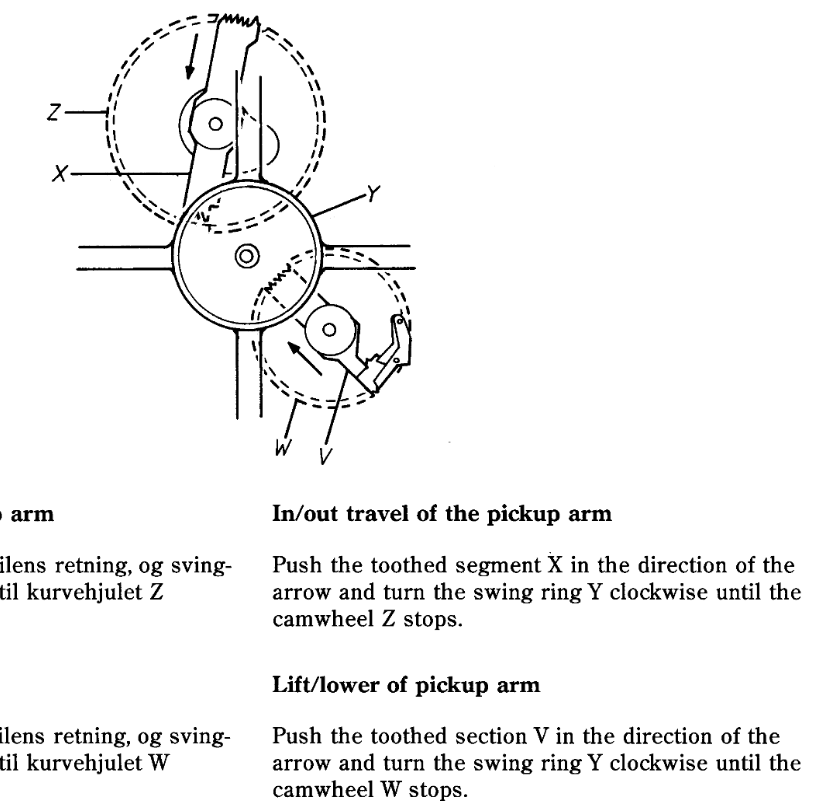

So there is another adjustement that might help but I am not sure. I refer to picture below. Since the arms are skewed and I cannot see any reason straight away why. I hope I can get around the problem by making more adjustements.

I see there is separate adjustment for start position. That I adjusted as far as it can be. It helped a little. Needle is just about over the record.

But there is described the arm movement adjustement. Can it help to solve this problem that arm could go a bit further over the record when starting playing. I havent had the courage to try that adjustement.

-ismo-

I have the manual that has mechanical photos etc. But cannot really see how it is possible to twist the whole arms module couple mm’s back to correct position. As said the arm does not go parallel with the housing of the player. The arm module is on those rails beneath it and rails seem to be ok.

-ismo-

Thanks for fast answers.

Ismo

Hi,

I have no clue about that optical shutter issue and how to check it. I can try 45rpm records, theres couple of those. Capacitors are not changed. Is there any cap kits available for LP player ?

-ismo-

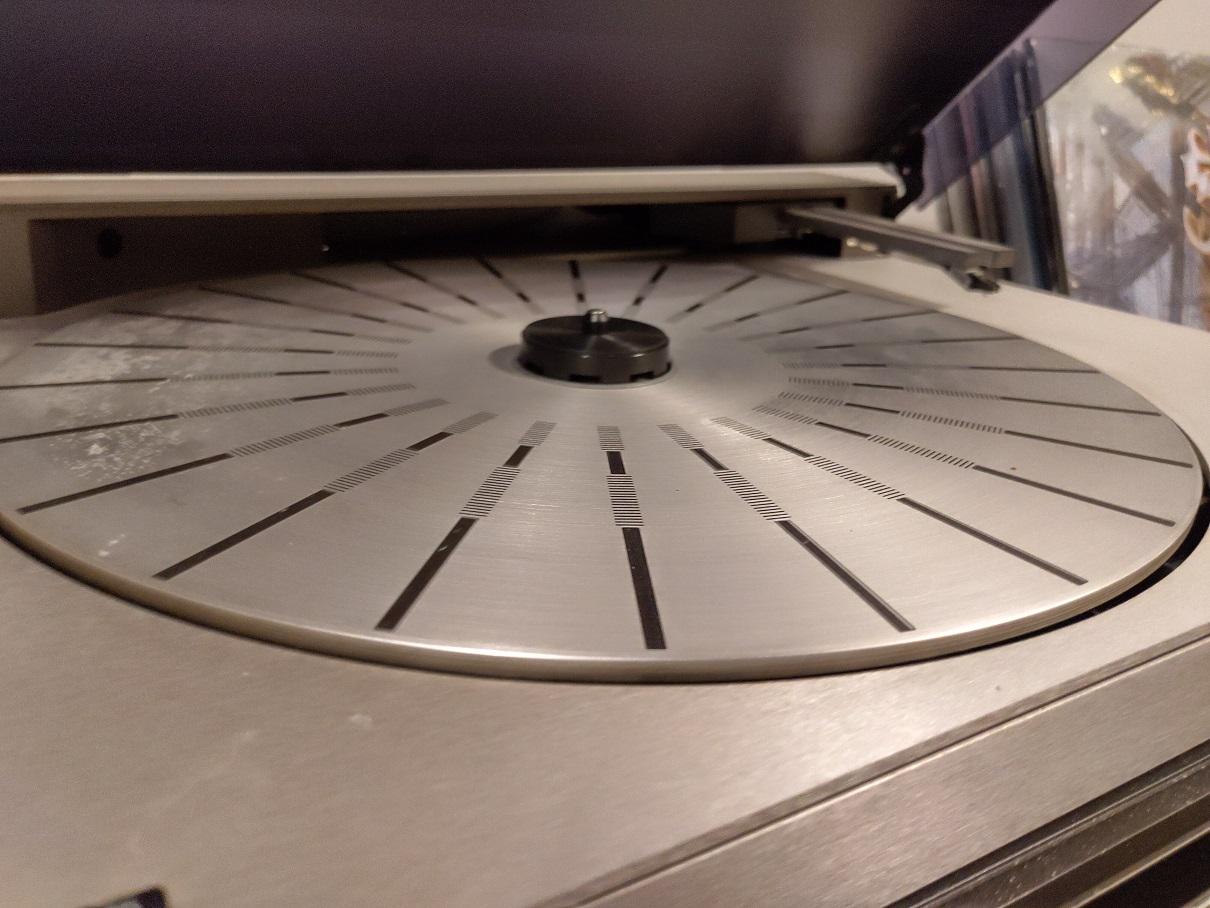

I also changed now the worn servo belt. I know it has nothing to do with this problem but all belts are changed now. I suspect that there are 2 possibilities, Drive motor is worn, or the voltage of drive motor is not stable. Dont know about is there any signal/control line in motor connector. The platter is adjusted high(see photo). Could measure the voltage with oscilloscope if I had one(multimeter resolution/speed is not high enough). Maybe dismantle and solder all on pcb like on that CD player when it helped…dont know.

Unfortunately I am away now but next weekend I try to take photo. I saw a similar photo here before and after adjustment. The latter looked as my player. I had this clunking sound at the end of play and then I adjusted that platter higher and centered. That helped back then. I still believe its the drive motor fault. 2 new belts tried out and no change. I also ordered new servo motor belt just because it was worn also, waiting for that.

-ismo-

I have adjusted the platter higher earlier. Tha caused different error back then. I dont think that is the case this time.

- AuthorPosts