Forum Replies Created

- AuthorPosts

-

Hmm – I tried to do what you wrote. After putting it together there was no change. However, I did have some success – not sure why.

After covering the light sensor, I could see that the take up reel was spinning both during play and fast forward. Maybe there is some misalignment somewhere as the eject mechanism was actually in the up position (as in no tape there). I then put in a tape, and it would fast forward and reverse. Screwing down the eject mechanism, I could hear that the forward motion started to struggle, so I didn’t screw it down completely. Play still chewed up the tape as the take up reel would not move. I ejected the tape. Inserting it again, I could hear the motor spinning when fast forwarding but again the tape would not move 🙁

The FS arm is the blocker. It does move away if I turn the small motor to the right.

The FS arm is the blocker. It does move away if I turn the small motor to the right.

However, the damn thing wont either forward or reverse. I am clueless at this point.Yeah – that thing flew right off a few times but I found it. I glued it back on.

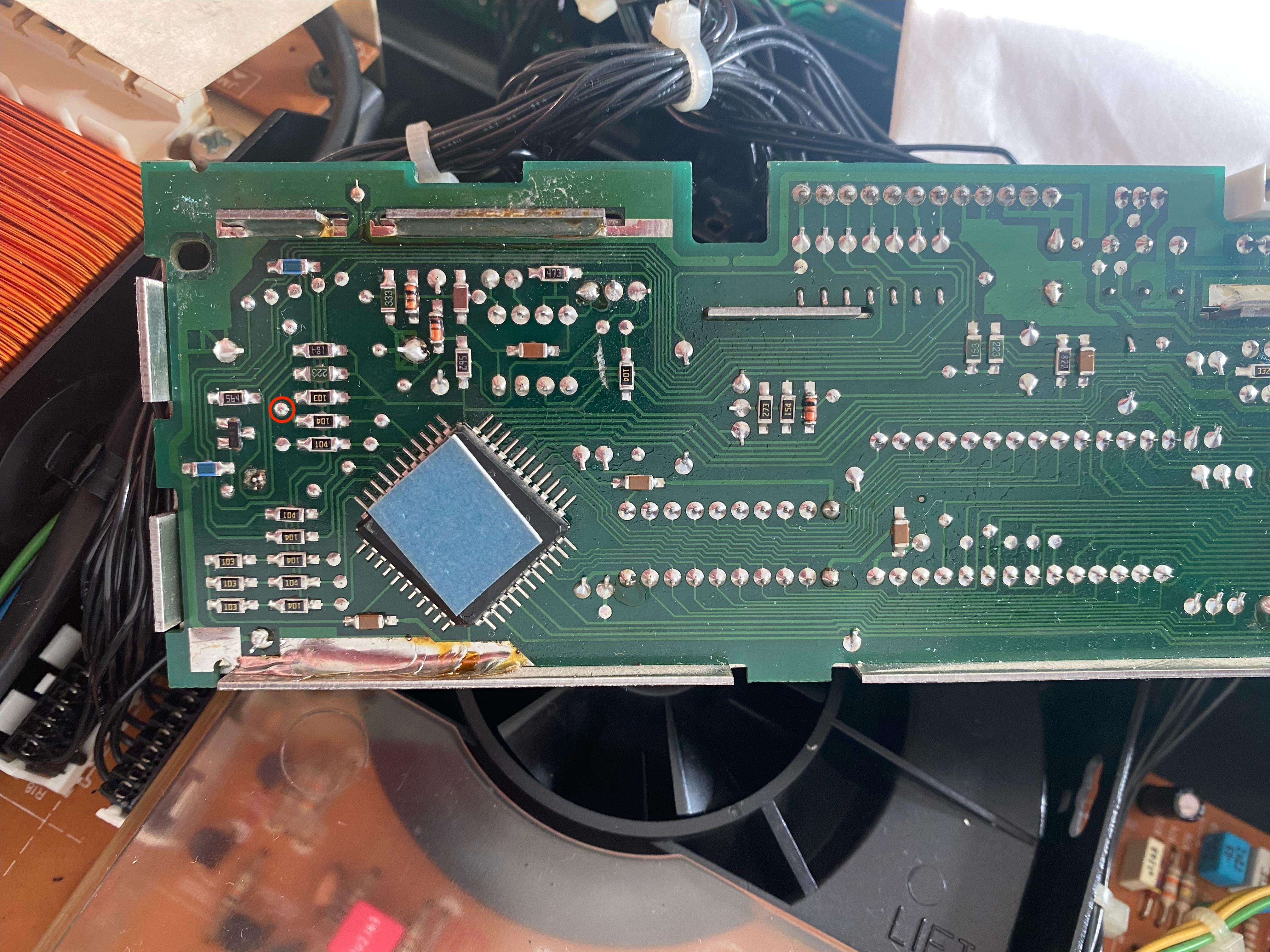

Here is a pic of the gearbox:

The symptoms are:

- Play works on the left reel but the take up reel does not move, so the tape soon becomes tape salad

- Fast Forward and Reverse do not work. I can hear the motor spinning but the tape does not move.

As a side note: the VX7000 that I received was also eating the tape. The reason was hardened grease under the take up reel. After cleaning and lubrication, the tape is no longer eaten. Anyway, I am not so interested in the VX7000 as its functions are very limited without a suitable Beovision.

Thank you, Martin – but I was lucky enough to get a VX7000 for free today, so I have taken the mechanism from that one.

However, I still have one problem:

The reel drive gear is driving me a bit insane. I cannot get it to touch the take up reel. I have looked in the service manual but there is definitely something that I am not seeing. Any tips? Seems like there is a plastic hook underneeth the right wheel that prevents the change.Here is a video of the problem

Looking further in the Service manual, it says to carry out functions 16 and 7 in test mode which I have not done. Could that be the reason for RDS not working?

I managed to fix it. I had to remove the metal shield to get access to 4TP1 and short circuit it to ground. Now the frequencies are correct. RDS is still not working.

Perhaps the crossover filter needs a recap. Since the sound is not great regardless of using the amps or not, it points to either the crossover filter or the mid foams IMO. The placement and distance to walls can also affect the sound.

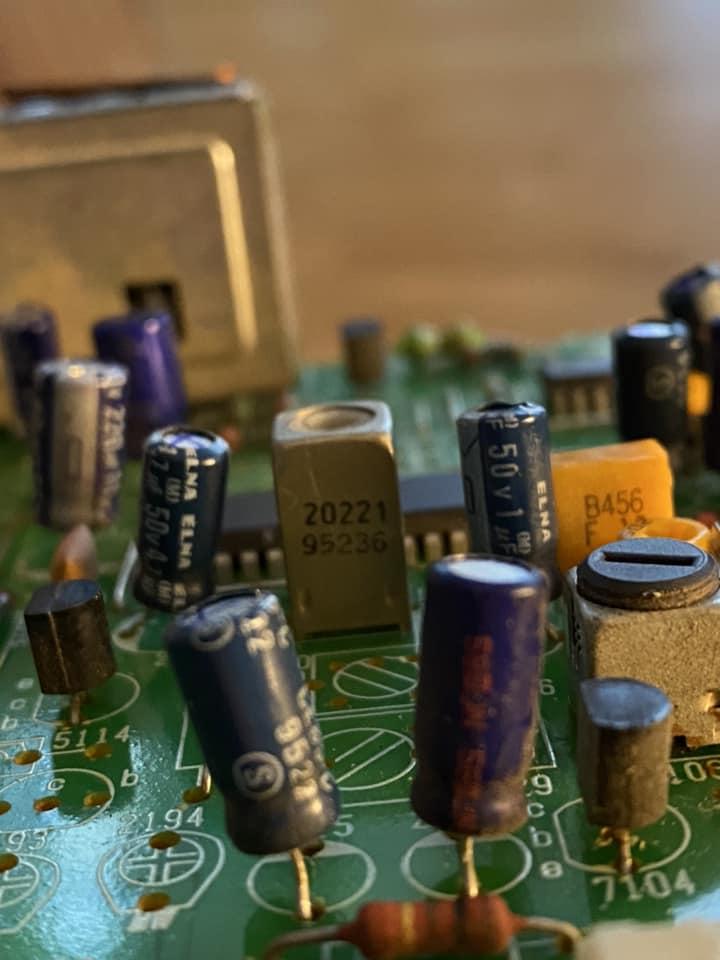

I finally had time to check the FM board. What a hazzle to get it out. Removing 16 screws marked A – some of them quite hidden.

All the caps on the board test fine – that is the good news.

I am pretty sure that the fault lies in the square part 5105 which is just called ‘coil’ in the service manual. It is an IF can with a condenser, and it seems that the condenser in these dies for whatever reason. Since I don’t know the specification, I don’t know if a replacement part can actually be ordered from somewhere, or if it can somehow be repaired by replacing the condenser. Anyone has an idea?

I will PM you.

Is it possible to get a new one 3D printed?

At this point I am ready to toss the whole thing and not spend more time on it. I think it’s the plastic part that I glued that is not completely accurate.

I think mine looks identical.

Here are a couple of videos of my loading mechanism problems – I don’t know how to embed the videos. Sorry that the speak is in Danish. What I basically say is that the mechanism is jammed, preventing the tape from being the item that unlocks the mechanism. However, if I turn the wheel under the machine, it will unlock and work.

https://youtu.be/gVU-HhJbuJs (mechanism out of machine)

and

https://youtu.be/wsfIXUdFwMU (mechanism in machine)

Haha – no, I mean on the left side, seen from the front.

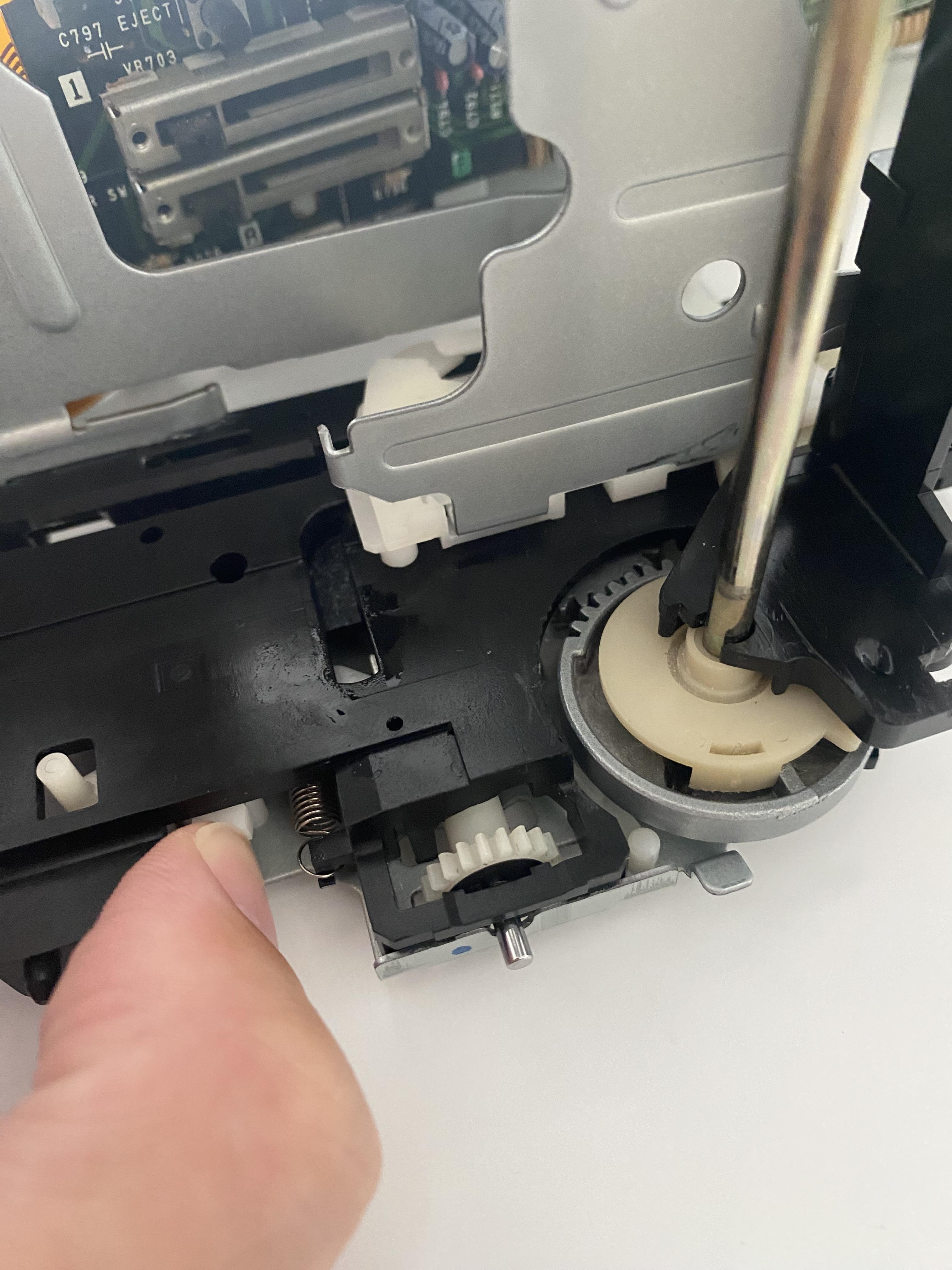

My problem with the loading mechanism is definitely the white worm wheel. The mechanism is smooth without it. Once it is inserted (correctly with the timing mark), the mechanism will become unstable and lock up in the right side. I am not sure if the spring part under it is assembled correctly. Any help is appreciated.

Also I noticed that the VX 5000 is getting very hot in the left corner away from the mechanism. Is that normal?

The gears are adjusted exactly like your picture shows.

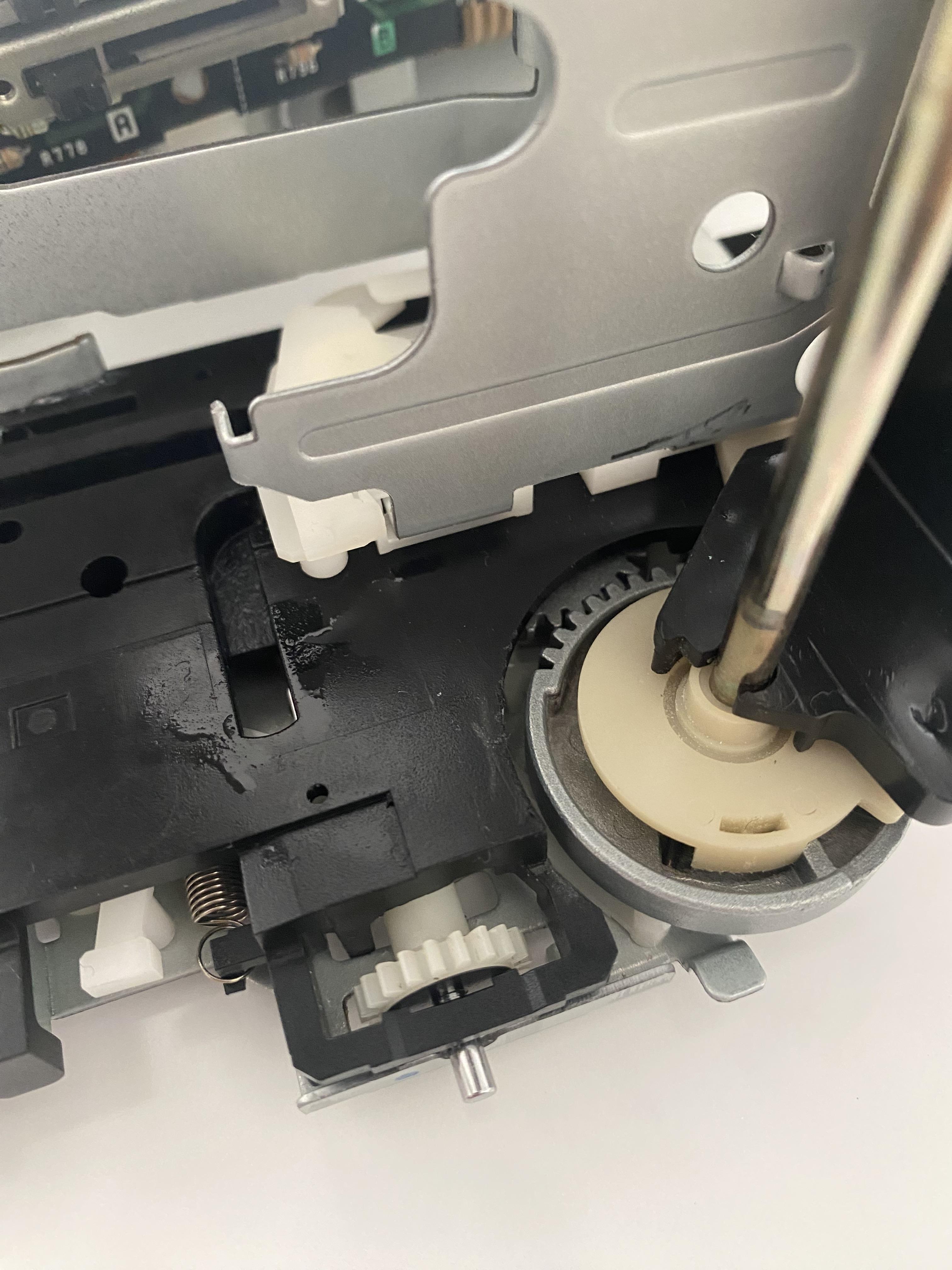

As you may remember from above, I had a broken drive gear. I tried to epoxy it but either my epoxy has turned bad or it was not mixed in the right ratio – in any case it was not strong enough. But, hey – the Internet and YouTube came to my rescue. I tried the – new to me – old trick of using super glue and dipping it in baking soda. Incredibly, it turns hard as stone instantly and the part was again useable. Wow!

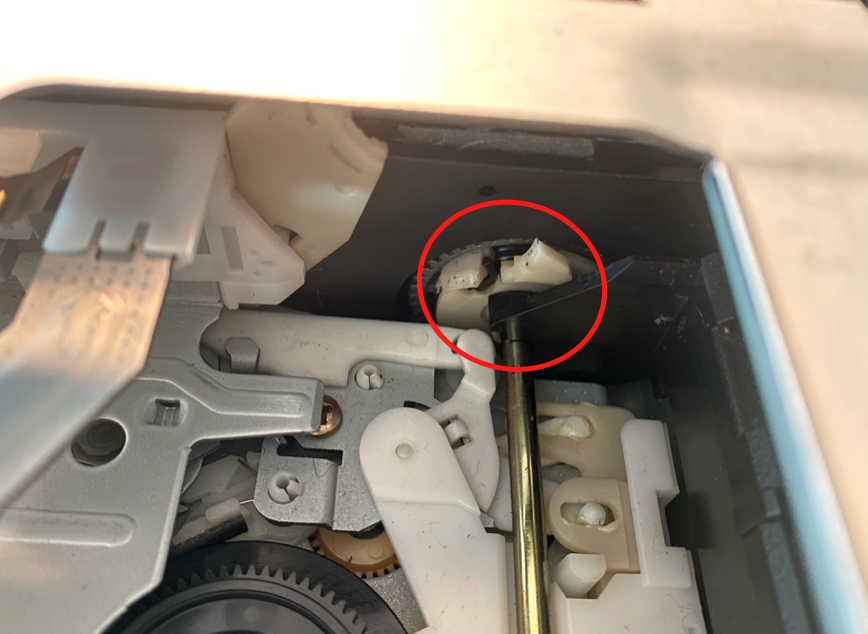

Here’s a picture:

But I still have a problem with the loading mechanism, and I think it is because I may not have assembled it correctly – perhaps the spring in the drive gear is the problem? The symptoms are:

- the mechanism seems to be locked in the right side, so I can’t get the machine to accept a tape.

- if I manually turn the big white wheel under the machine – called the clutch assembly – the mechanism is not locked. The tape moves in a bit and the machine happily engages the loading motor and accepts the tape.

Why not just clean the lens from both sides. Look up the thread about fixing laser on Beosound 9000. There’s a video that shows how to do it.

And … there is a broken piece of plastic in the insert/eject mechanism :/

I wonder if it can be epoxy’d together ….

But of course that will not fix the speed fluctuations.

So, I got the belt for the capstan motor. The great news is that the tape loads, the counter counts, the VU meters work, fast forward, rewind and eject work BUT the bad news is that the speed is changing and there are dropouts on the Hi-Fi track. Is there known error for this? I closed the deck and tightened the screws, so I did not check if the bolt is attached to the guiding pole which was mentioned in the old thread about how to repair the VX 5000. I guess I will need to open it to see if that bolt has come lose and is hidden somewhere in the machine.

- AuthorPosts