Forum Replies Created

- AuthorPosts

-

Will it play for only one or two platter revolutions or can it play a minute or more?

If only one or two revolutions;

– Damaged needle tip

– Wrongly set tracking force

In the above mentioned cases the sound will almost always also be bad/distorted.If a minute or more and the < and > buttons work fine:

– Tracking lamp/opto-interrupter badly adjusted (needs adjusting after replacing lamp/opto components – see the servicemanual)If a minute or more and the < and > buttons only lifts the tonearm but doesn’t move the carriage:

– Bad carriage motor belt

– Bad carriage motorNo sound at all – check that the needle actually touches the record.

Martin

Did the smell come from the drive?

Can you still smell where it came from?It’s not uncommon to see the ribbon cable damaged where it is held by the black clip.

The cable goes around sharp corners and it takes only very little pulling to damage the cable.

It’s also very short – only long enough to reach the board socket. Inexperienced repairers

can accidentally pull it when dismounting the board from the drive, because they may

not know the cable is there.

I would check the cable on the drive that wasn’t burned.Martin

Hi i am new to the forum, I have been reading the different topics without luck on finding the issue I have, so decided to open this topic, thanks in advance for your support. I got a Beogram 6000 from a neighbor who did not have the time a patience to try to fixed it. It is in fare condition I must say, but I notice different hands try to make it work with no luck. Anyway, at first I saw the bulb on the detector arm was not working, easy fix, follow the circuitry and found the zener diode ID09 broken, replaced it along with the TR10 transistor and voila, detection of LP works again, disc are detected and the arm lower properly. I also replace main electrolytic capacitors, filter C1, C2, C3 at the motor and the bipolar C4 along with C13 to C16. Now, the big issue I have is that after some time playing music, the transformer gets really hot and the fuses blown. From the beginning I found weird, and still, that the chasis is not connected to the negative part of the circuit. Inspecting the schematics, the only clear physical-electrical connection to the chasis is through 47nF capacitor to the shield of the cable that goes to the amplifier. Am I missing something here? How I am suppose to measure voltages and signals to chasis when clearly there is no electrical connection between them! That puzzles me, and I am not sure this has connection with the overheating of the transformer, I believe so, but I cannot find anywhere in the service manual other electrical connection to chasis. I would really appreciate your advise and comments, time being I will start replacing old capacitors. I suspect of the solenoid circuit that is draining too much current, but at first seems to be ok… thansk Christian

The chassis is not signal ground.

Don’t use the chassis as ground reference when measuring.

The capacitive coupling is correct.Apparently something is pulling too much current.

If the motor phase is set correctly you will have to separate circuits to see, what is pulling a lot of current.Martin

You can replace the cord if you are handy.

Martin

I’ve lubricated the center cam wheel, maybe I shouldn’t have?

You shouldn’t.

These cams MUST run dry and clean.Martin

Watch the motor current draw!

As Soren suggests; If the belt is wrong (too tight), the motor will see a too heavy sideways load, and its bearings will go bad in no time = goodbye motor. I’ve seen it so many times with cheap junk belts from Portugal and Germany sold in large numbers on Ebay etc.

Speeds being low after replacing the belt could suggest this kind of situation.Martin

You get the new fabric in the same way. Pressed in using the alu trim.

Clever? Yes.

Elegant? Yes.

Easy? No.I have had a little success first glueing the new fabric in to the ridge on one side,

then, when set, work to the opposite side etc. and fit the alu trim last.Martin

The drive stops because no tape motion is sensed.

– Bad belts

– Bad motor

– Lack of power to the motor (bad fuse)

– Seized take-up reel

– Cracked solder joints at the connector to the drive

– Broken off lead for the motion sensor

– Any combination of the above.

If it happened after shipping, I would check if the motor is running when the deck is

out of standby. If it doesn’t check the fuse on the regulator board – and its holders.But I agree, the seller should help you with this or take it back.

Martin

The fabric is held by the alu trim. You can ease the trim out carefully.

And they don’t look like Beovox 2400.

Martin

No. First take off the alu trim. The cloth is held in the ridge for the alu trim.

Martin

Well, judging from that photo I’d say the platter rides a bit too low – at least at the left side (facing the camera).

Bring it up 1-1,5 mm at the left and perhaps also at the rear leaf spring and let us know how it works out.Actually, a very low platter setting has often caused wow.

Reason: A 12″ record is a larger diameter than the platter and the wow comes when the record touches the

surrounding surface – gradually increasing as the tonearm and carriage move inwards, shifting the center of gravity. First tracks play fine, later tracks not.

The solution is to tighten up the suspension a little at the left/rear.Don’t overdo.

Make sure the subchassis is still able to move freely.Martin

Unfortunately, there is no industry standard for 12” record weight. They can range from 80-200g.

What? What makes you say that?

Just because you can buy records weighing in from 80 to 200g doesn’t mean that it’s a standard.

I have played a custom made record weghing more than 1Kg for a customer once.

The RIAA standards are fairly clear.

And you’ll be surprised how much is non-standard.Martin

180gr records are non-standard.

Most decks can be made to play them but, ideally, if you adjust the suspension to suit 180gr records,

you should put it back again to play standard records, because the subchassis suspension carries both

the record, the platter, electronics and carriage of which the latter shifts the center of gravity of

the whole subchassis when moving.In your case I would tighten the suspension just slightly on the left and rear leaf spring.

Martin

It’s not uncommon to see different drives used during production, but this one

looks original for a Beocenter 9000.

Only Beocenter 9000 has the spring clamp. All the other Beocenters in this series have the

door-operated swinging clamp.Other minor differences can also be found, making collecting these interesting.

Martin

The lamp sits inside the black plastic housing at the backside of the frontpanel.

Interrupters block the light from the lamp to the LDRs when buttons are pressed, and the screws are for adjusting (ref. service manual).

New lamp here.Martin

Capacitor C2 on module 53.

Martin

Replace 53C2 (47uF).

Martin

I would not enjoy being interviewed as such, but I don’t mind showing a few of the more exotic products, I have come across, if it could be of interest.

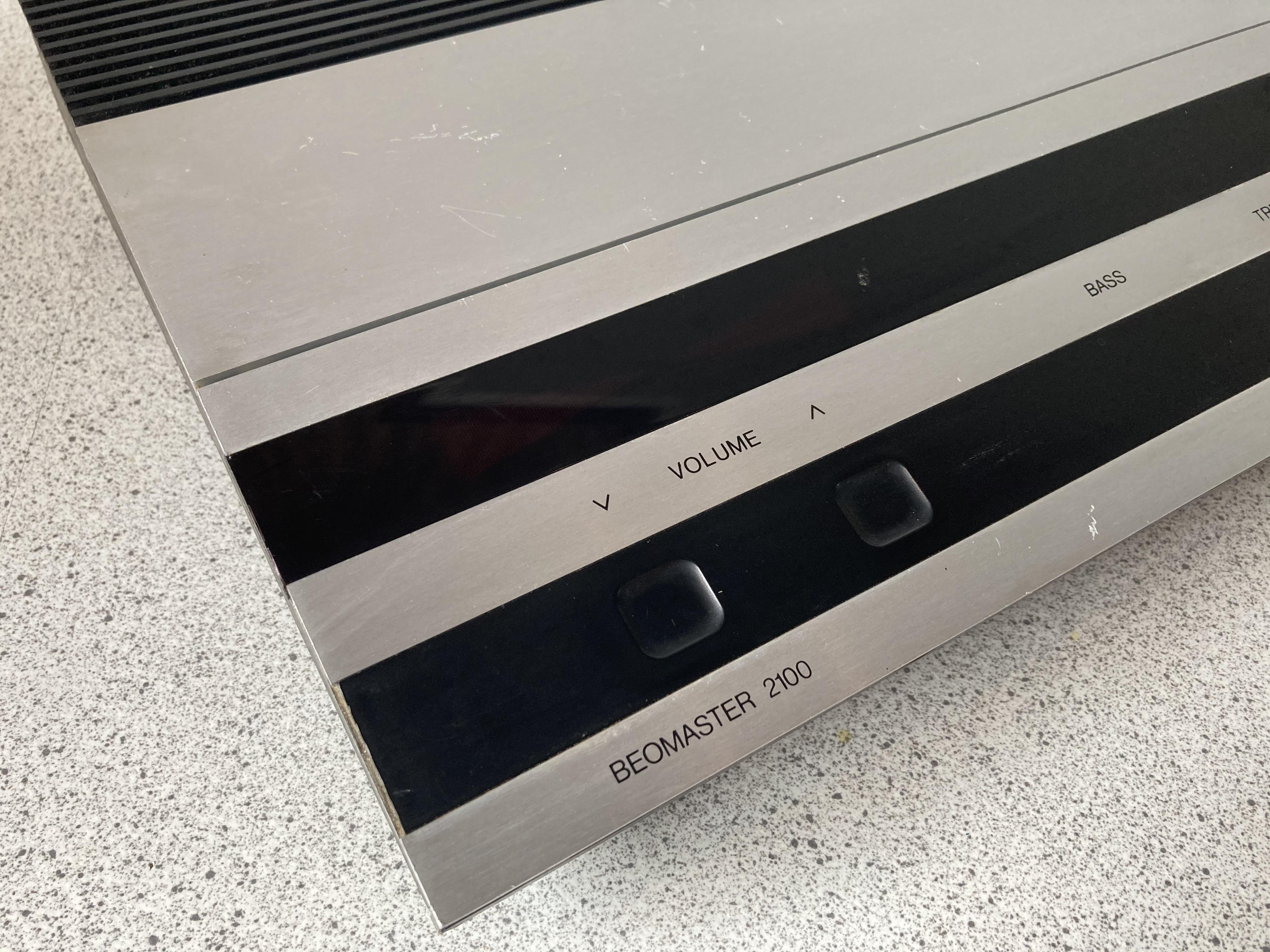

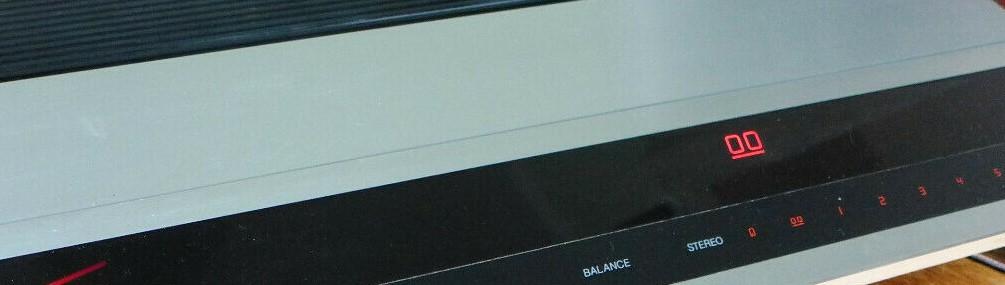

Beomaster 2100 (prototype)

Beocord 1900 black edition (as found, before I carefully cleaned it up).

Presumably an attempt at a matching cassettedeck for Beomaster 2200 and Beocenter 3300.

Beomaster 2400 first edition (with different symbols). I have the matching remote control too.

Record player G46SR

Martin

Yes, that’s what I did and found this:

https://www.facebook.com/soundsheavenlycables/photos/pcb.5676106309106059/5676099505773406

What is the (presumably) S-model near the camera, with the Master 38RG, Master 39S and JET 512RG in that order behind it?

Martin

- AuthorPosts