Forum Replies Created

- AuthorPosts

-

The jumper determines left/right. So you can check loudspeaker versus BS2500…

Maybe a good idea… replace this smd c(r)ap with something more reliable…

23 October 2022 at 06:29 in reply to: BeoLab 8000: 5-pin cable from RCA-PCB to LED-PCB sensitive #39851Solder it.

Hum is just some millivolt.

Copper, mixed with chromeplated steel and nickel will always make some chemical noise.

You can also make a special shortcut plug for testing. Just a shorted Cinch connector.

Then you can test wether there is still humming…

There is no quick fix, unfortunately. Check the treble amp, its level trimmer, and the wiring too.

Confirmed.

But even if it was playing louder (level trimmer wrong…) it would not fail so easy and blow the tweeter… there is more. Tweeter fail because of a DC offset on the signal.

Check for DC direct on the tweeter.

And it would make sense to connect a small 12V bulb parallel for testing. It would show the fail of the amp if glowing.

The aluminum is eloxated. Very hard oxyd. Cannot be painted, no paint will stick on this oxyd. It will chip off easily…

You have to grind it, better is sandblasting with glas, not sand or steel.

As mentioned right before: you need a etch primer, then aluminum can be painted.

On the etch primer you can use almost every car paint… 2K.

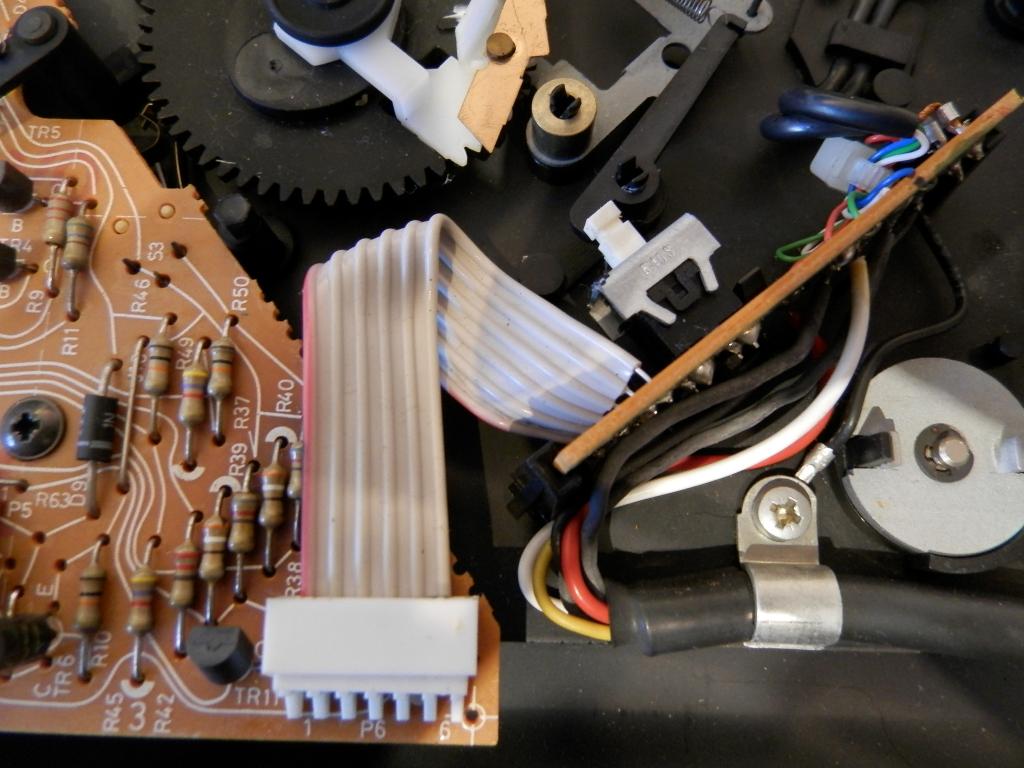

16 October 2022 at 05:30 in reply to: BeoLab 8000: 5-pin cable from RCA-PCB to LED-PCB sensitive #3984616 October 2022 at 05:14 in reply to: BeoLab 8000: 5-pin cable from RCA-PCB to LED-PCB sensitive #39845Check this board and the LED board for broken solder pins/pads. Especially the ground pins… and use a magnifying glass… BL8000 have lots of problems with broken pads. More or less ALL active loudspeaker have this problem. Sound is stress to solder pads, it’s mechanical stress and it is just a matter of time and played volume…

… and for the acid foam. Maybe broken lines in the preamp section…

When i remember right: there is a timer function in the drawer motor control.

It is started for around 2 seconds , in -and out, toggled.

It does not detect overload or a position. Just 2 seconds motor on…

I think: typical cap problem in the motor control…

You have cleaned the acid of the smd caps?

Tantalum ist very expensive, big and very longliving… 🙂

Tantalum hates spikes, overload and mechanical shocks. But this is here not the problem. Much better than this smd elko crap…

the rubber is done because of mechanical tolerances. The screen rubber will also work, but not so long… silicon screen rubber oxidates faster, but will also work for this.

It is also something like a fuse. Inside the case is a carbon paint for capacitive action. You should check it for cuts and breaks. It can be repaired with silver for windshields.

Caps make shorts and this depends on the voltage and temperature…

You have heard about “selfhealing caps” with polystyrene caps? Some elko caps do the same … and trick you out. It will happen again.

Metall oxide or wire resistors dont burn… coal resistors do burn.

There are 2 brown caps, the 220uf is prone to fail… yes, with shorts killing the resistor.

I have repaired dozens of them. It’s always the same. Caps defect.

Especially the SMD ones on the ir unit are the worst ever…

Check the capacity of them very, very exactly. There is a ” .. , ..”

I replaced them with X7R SMD caps … no electrolyth any more…

The motor is running as long as the source is tape … playing or stopped, the motor is running.

If source is different to tape, then the motor stops.

Contact… make photo !?!

Hmmm, the left one is ok.

The right one is somehow “blocked”, there is a hard stop in the membran. Maybe it was overload or somebody crashed into the loudspeaker.

Does it move by hand?

deleted

Without load… yes.

It’s a 2-coil transformer, for around 2 x 20V 150mA .

You start a Beogram to play without a record?

Nice, you will destroy the MMC if it continues.

That’s a safety feature.

- AuthorPosts