- This topic has 148 replies, 64 voices, and was last updated 8 months, 1 week ago by

TrebsT.

- AuthorPosts

- 22 January 2023 at 10:02 #36841

I have used larch wood, I am very much impressed how easy it was to give them a modern look! Thanks again so much for sharing the 3D files and the awesome user manual!

22 January 2023 at 10:34 #36842

22 January 2023 at 10:34 #36842Thank you drmichi for showing us your work.

Nice shade of wood and beautiful Beocorner you have there.Enjoy.

22 January 2023 at 12:30 #36843@matador Wouldn’t it be better looking if you also design/print (with black PLA/PETG/ABS) the top panel instead of using piece of black cardboard cut to shape?

Would it be possible to add this to the design?

What thickness (in mm) would give us the best/flush look? 5 February 2023 at 06:02 #36846

5 February 2023 at 06:02 #36846hi mate can you make me those 3d Plastic wood holders for two speakers will pay you of course ,because i don’t have 3d printer the rest of the work will do it by my self thanks let me know please ha e a good one

12 February 2023 at 12:51 #36847Thanks for these. It is just amazing. Can please someone do it for 6000’s?

27 February 2023 at 06:54 #36848Hi @matador!

May i know the difference btw the 5mm files and the 4mm files?

27 February 2023 at 07:27 #36849The 4mm clamps are designed for 4mm thick wood bits.

The 5mm clamps are designed for 5mm thick wood bits easier to find in nothern countries it seems.

2 March 2023 at 05:06 #36850I was comparing them and it appears the “curve” is smaller and flatter on the 4mm vs the 5mm?

Does this mean visually it will look like a bigger and more curved?

2 March 2023 at 08:20 #36851The 5mm model was developed by another member from my design, to fit local wood supply so I can’t really say. Nevertheless, there is indeed a strong link between curve, depth, wide, number of lamellas and their thickness, so it make sense the curve is more important.

And yes it will result in a less thinner speaker. To what extend ? I dont know.

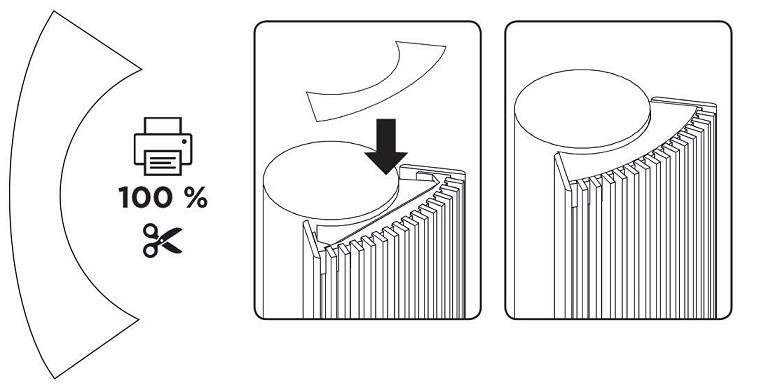

17 March 2023 at 07:16 #36852Hi everybody..I need help ..i have a question ..What is the true size of the top lid in the pdf document ..

I cant get it to work on the printer since its a long pdf doc ..I cant get the scaling right so if anybody have a stl or size doc for the normal printer or 3d printer or the laser file for the cutter can you please share it

Thanks.

20 March 2023 at 08:32 #36853What kind of ‘brackets’ are used on the beolab 8000 on this picture (the right one)?

This one hasn’t got a top-plate, so looks more like the original beolab 18. I like this al lot!

20 March 2023 at 10:04 #36854

20 March 2023 at 10:04 #36854It’s not about the brackets, it’s about the lamellas. They are rounded and must be L shaped at the top. I think they’re also very thin (not deep). All this to say that this solution involves a lot of woodwork and is certainly not 50€. But indeed the result has nothing to compare with my cheap solution.

21 March 2023 at 09:34 #36855You discovered the secret! I think you are correct. The lammellas have a L-shape on top. Looks good, but indeed a lot of woodwork…

I’m going to print your brackets next week and buy all the needed wood. We are going to make 2 sets. For my dad and for myself.

23 March 2023 at 01:09 #36857@matador Why are the slots in the 4mm only ~2.2mm deep?

Is this enough to ‘clamp/hold’ the lammellas firmly?23 March 2023 at 09:15 #36858At first they were meant to be a cradle to hold the sticks with a drop of glue.

But in the end the sticks did click in and stay firmly in place without glue.

The groove is not deep to stay invisible between the lamellas.

23 March 2023 at 10:10 #36856Hi all Here in Denmark it seems that 5mm frets are more easily available. I have therefore created clamps based on 5mm frets. I have created new STL files based on Matadors original clamp design, but slightly changed. They are 5mm wide, a litte deeper in the groove and more curved. There is also 3 clamps now. A Top, Middle and Buttom. The Top and Middle clamps rests on the speaker structure – and the Buttom just floats. You can choose to replace the Middle with the Buttom clamp if you wish. The clamps were made in Fusion 360. I have provided both the Fusion 360 files and the STL files. That way you can adjust the clamps to your specific needs if needed. Credits go to Matador for starting this. He also approved to add the files here.

@Lemme : Do you have pictures of beolab 8000’s with your 5mm brackers/final result looks?

I’m interested in how it looks compared to Matadors 4mm brackets, because the ‘curve’ looks smaller on the 4mm brackets…27 March 2023 at 02:40 #36859Hi Matador and community,

Thanks a million for sharing and uploading the files, this is amazing.

Not knowing anything about 3D printing I sent the STL files to a local printer. He says that the files do not have any measurements.

@styppen asked the question before and was also kind to share mm measurements for x,y and z. But what do these represent?Could someone please advice how I communicate the measurements to the printer?

Many thanks in advance and apologies for perhaps asking a stupid question.

Best regards from Sweden

J

27 March 2023 at 07:30 #36860The screen capture and measurement from styppen are right.

It’s the “bounding box” size of the whole object.

For whatever reason my export do not carry scale information and you have to scale it depending on your printer device. But it should usually be a round factor: x10, x100, x1000.

Anyway, give your supplier the bounding box size and it should work.

31 March 2023 at 05:22 #36861Looks very nice. I discovered, the chrome speakers looking much nicer with the wooden frets. Wirh the black covers they looking outdated. I have a black pair and that pair looks good with the original covers.

How can i obtain the files to make the fronts? I don’t know nothing about 3d printing but gonna ask a friend.

31 March 2023 at 10:22 #36862The files are here on this thread on page 1

- AuthorPosts

- You must be logged in to reply to this topic.