- This topic has 21 replies, 9 voices, and was last updated 11 months, 3 weeks ago by

Tignum.

- AuthorPosts

- 11 June 2023 at 07:41 #47113

Hi,

Replacing surrounds on CX50 (or CX100) you can many places choose between foam or rubber.

Was the CX50 from factory produced with foam surrounds? and would the characteristics of the speaker change notably by repair with rubber surrounds?Some claim that using rubber surrounds last longer but what about the sound quality?

What you you choose?/Pindsen

11 June 2023 at 09:08 #47114Hi,

The originals were foam type surrounds.

How noticeable the difference is will be purely dependent on the listener.If you are trying to keep things to the original design then stick with foam surrounds.

It would be interesting if you were to do one with foam surrounds and the other with rubber, then see if you can tell a difference.

Those are pretty easy drivers to replace surrounds on so it wouldn’t be difficult to try.

Plus, those being small drivers, the surrounds don’t cost much.If you do the test be your and post about it here.

-sonavor

12 June 2023 at 01:38 #47115The originals were foam, therefore I’d replace them with foam.

Changing to rubber will alter the parameters of the drivers and make them sound different. Whether this is an improvement or not is purely subjective.

12 June 2023 at 05:00 #47116Specifically changing from foam to rubber will alter the low frequency resonance changing the bass response.

12 June 2023 at 05:54 #47117I will try to compare and return with my perspective as I have both.

/Pindsen

12 June 2023 at 09:42 #47118Foam, where foam was used originally.

Repalcing with rubber changes the T/S parameters drastically.

If you only had the T/S to compare, you would never suspect it to be the same driver.Martin

13 June 2023 at 03:22 #47119What does T/S mean?

/Pindsen

13 June 2023 at 03:42 #47120BTW, one thing that has not been mentioned is that the lifespan of modern foam is likely much longer than the original foam. Progress in material science has advanced in the decades since the original surrounds were produced. Of course, one could still end of with bad surrounds, either foam or rubber, if purchased from a poor source.

Glitch

13 June 2023 at 07:02 #47121I also liked glueing foam more, as the glue goes into the foam and paper/carton, which made glueing the surrounds more easilly.

With rubber i often had spots i had to glue twice, with foam, always first time!

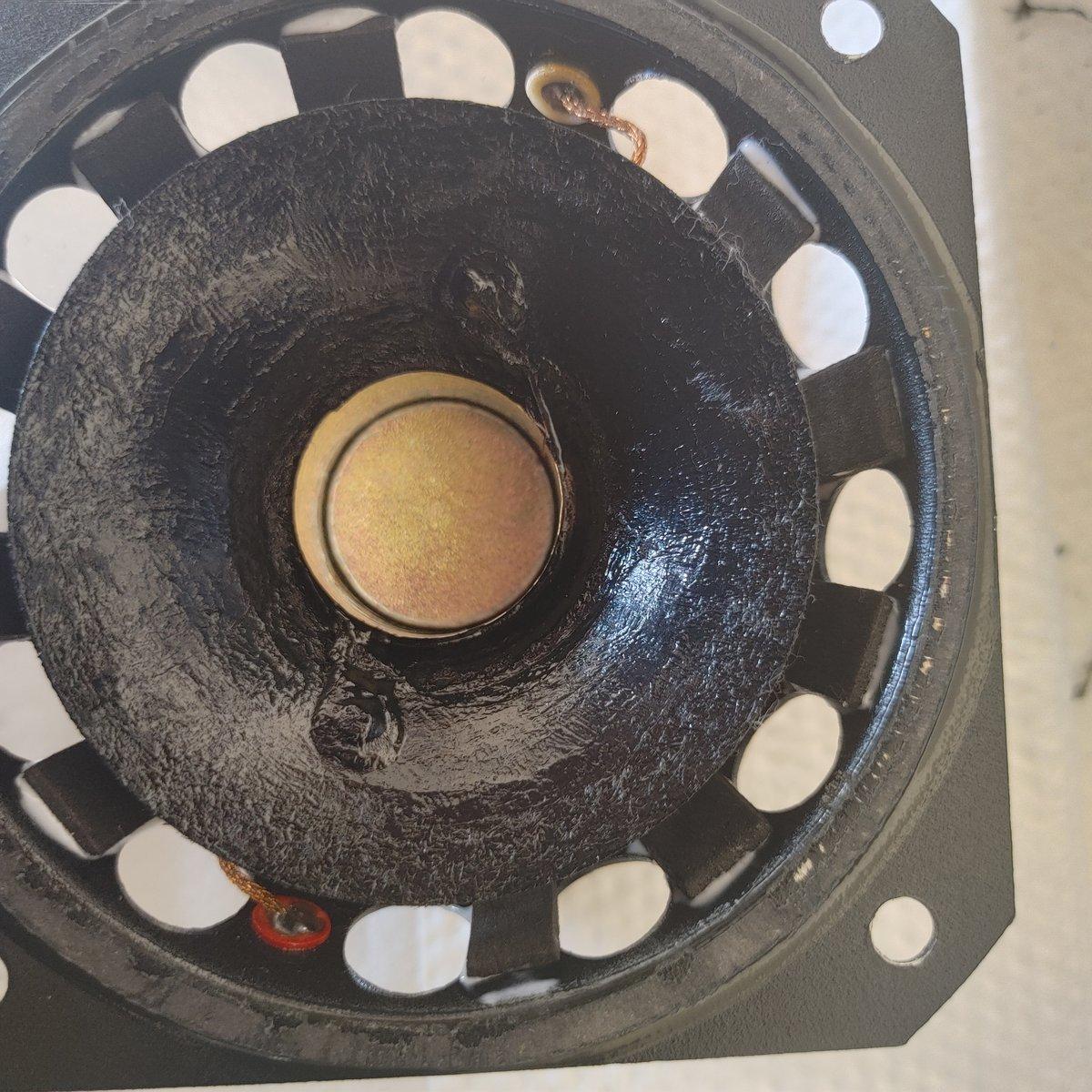

9 February 2024 at 11:08 #47122I changed my CX30’s and CX100’s to butyl surrounds and doped the cones. It greatly improved the midrange, yet slightly lowered SPL of the lower bass frequencies. Was a win/win running them with a subwoofer.

10 February 2024 at 02:32 #47124

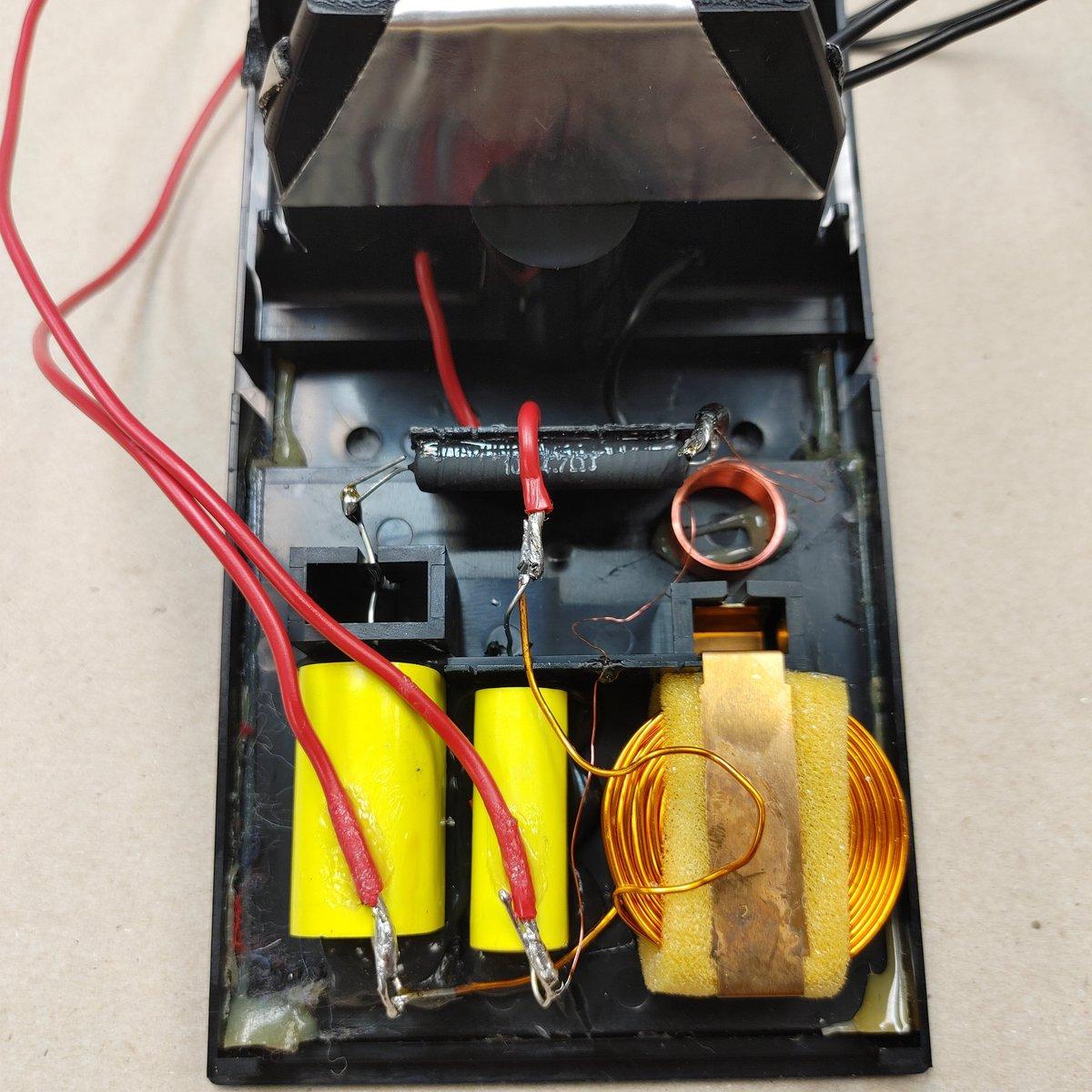

10 February 2024 at 02:32 #47124- Thank you. You did a fine job yourself, takes Alot of patience. Yes, I painted the frames satin black to match the cones. I rebuilt crossovers with film caps and wire-wound resistors. I also machined and phase-plugged the midranges, as well as foamed the inner baskets frames for ultimate clarity. I’m running them in conjunction with a rebuilt Polk RM-1000 subwoofer and custom tpa3255 amp to match aesthetically. Pure audio bliss.

10 February 2024 at 08:30 #47125

10 February 2024 at 08:30 #47125- Thank you. You did a fine job yourself, takes Alot of patience. Yes, I painted the frames satin black to match the cones. I rebuilt crossovers with film caps and wire-wound resistors. I also machined and phase-plugged the midranges, as well as foamed the inner baskets frames for ultimate clarity. I’m running them in conjunction with a rebuilt Polk RM-1000 subwoofer and custom tpa3255 amp to match aesthetically. Pure audio bliss.

I find this interesting,

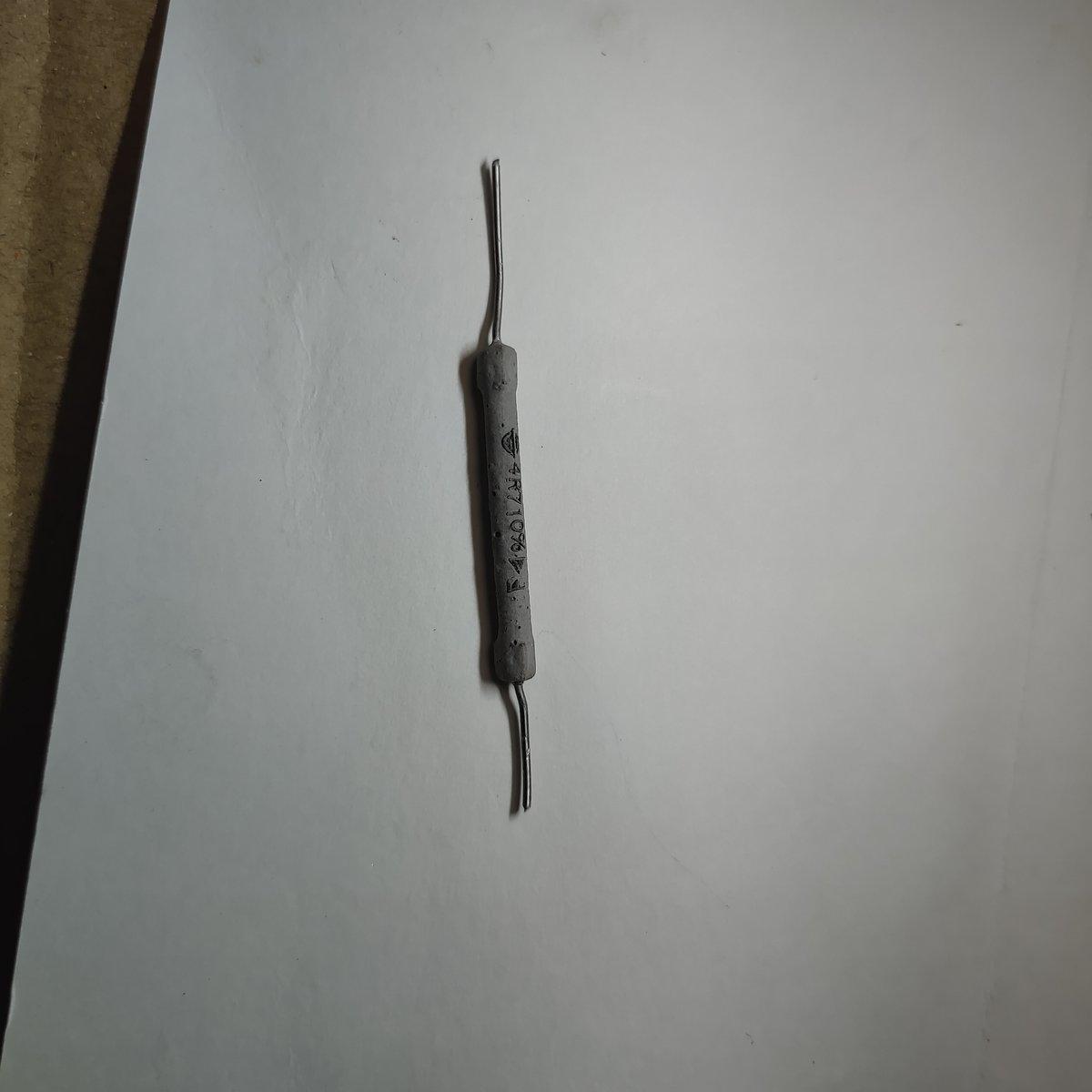

– a few questions if you don’t mind:Wire-wound resistors – where?

“machined and phase-plugged the midranges”

What is that, exactly ?

Is that the cone shaped thingy? If so, can you tell what improvement this provides?“Foamed the inner baskets frames for ultimate clarity”

Interesting, – what is the theory behind this?

And do you have any before and after values that would cast light onto what improvement this provides?Martin

10 February 2024 at 10:04 #47123Clean job xschop! Did you repaint the metal fronts of the drivers?

I lately refoamed these for a colleague. About time 🙂

I just touched up the metal of the drivers with a black marker as they will be playing with (freshly washed) frets.

11 February 2024 at 01:05 #47129Oh indeed, typing on a smart phone renders one inattentive at times…

The CX30’s have a 4.7 ohm cast resistor in their crossover. I added the wire-wound resistor and new film capacitors as well…

<!–more–>

<!–more–>After all said and done the CX30s trump the modified Polks

even with their exquisite sound signature and especially their tweeter’s sound reproduction

even with their exquisite sound signature and especially their tweeter’s sound reproductionaccuracy…

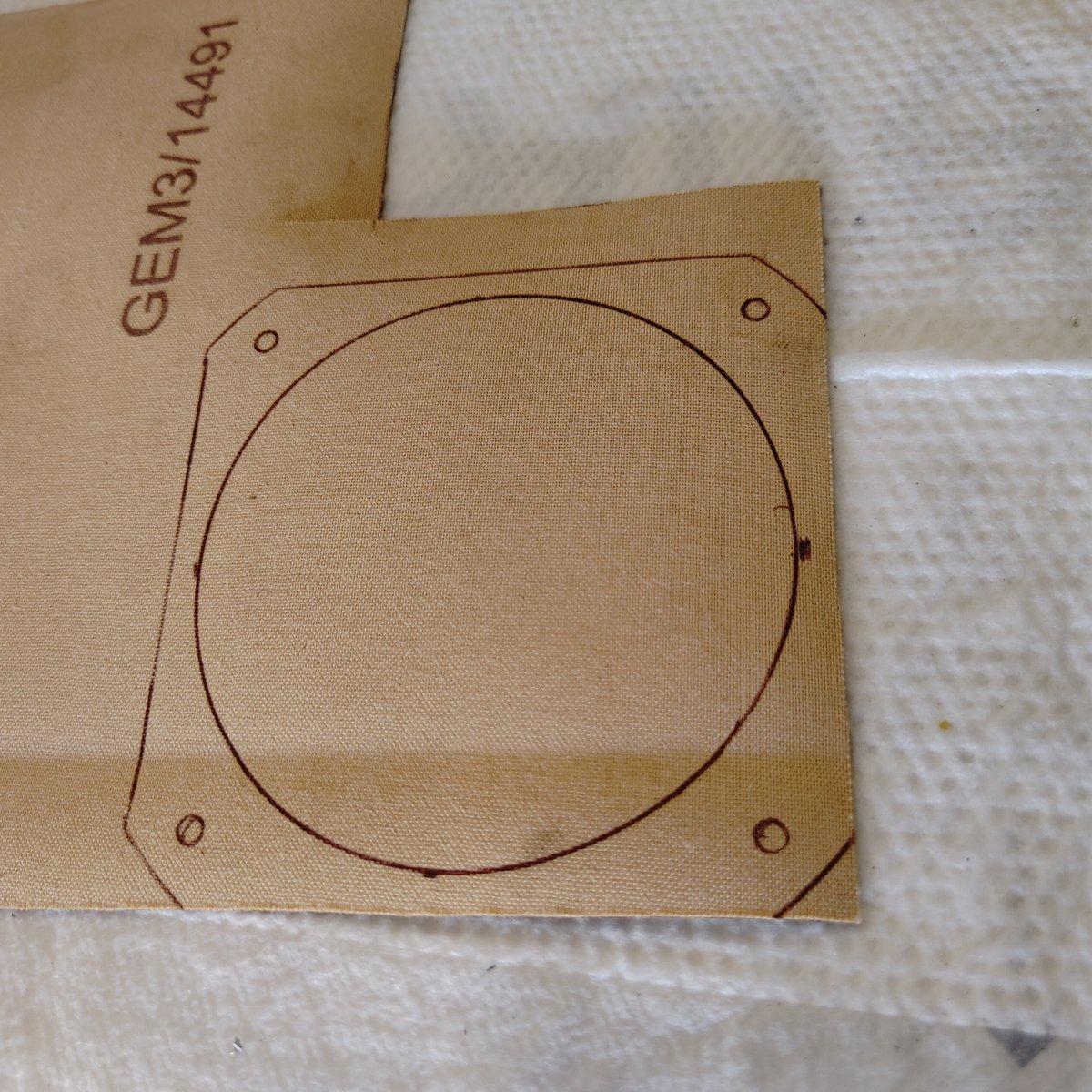

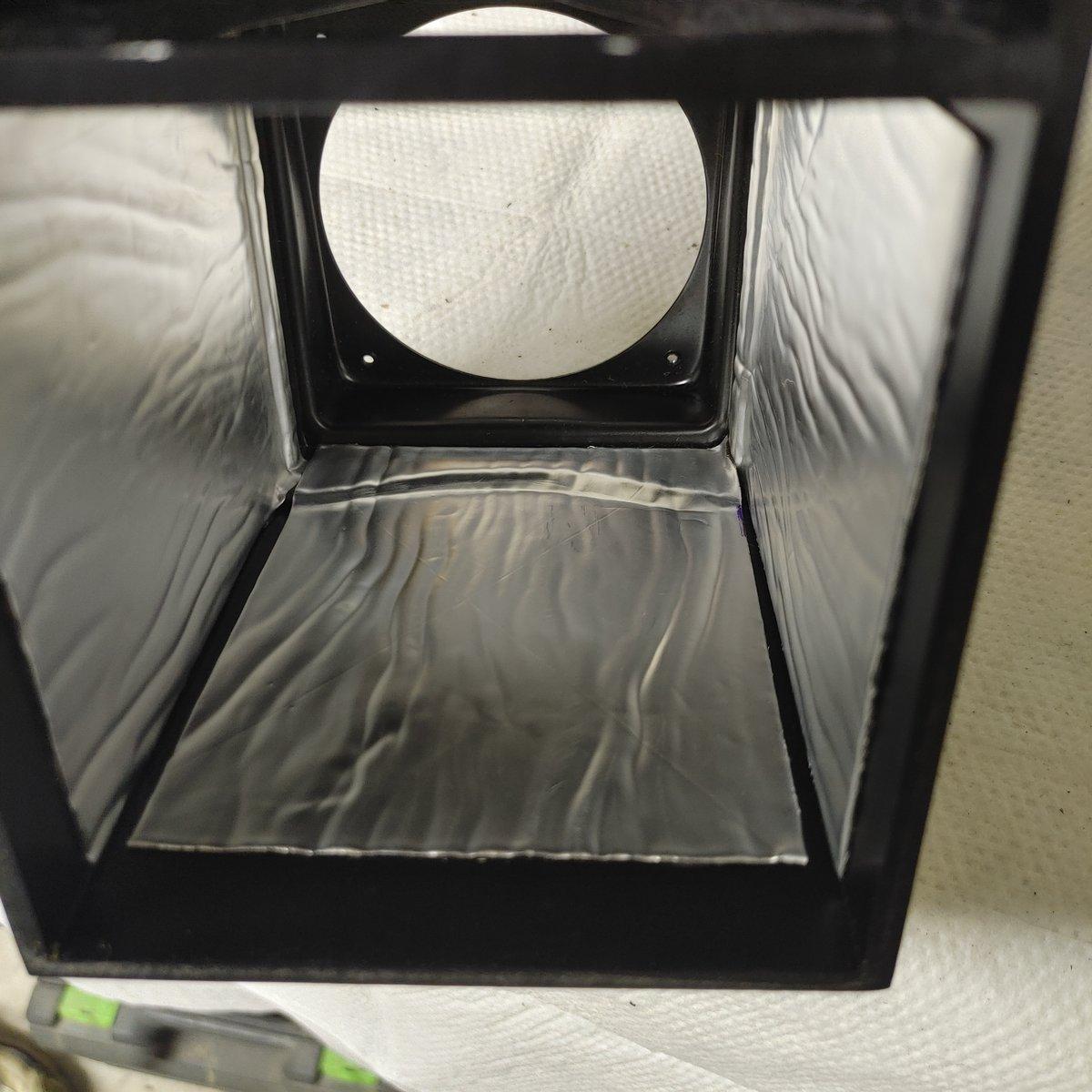

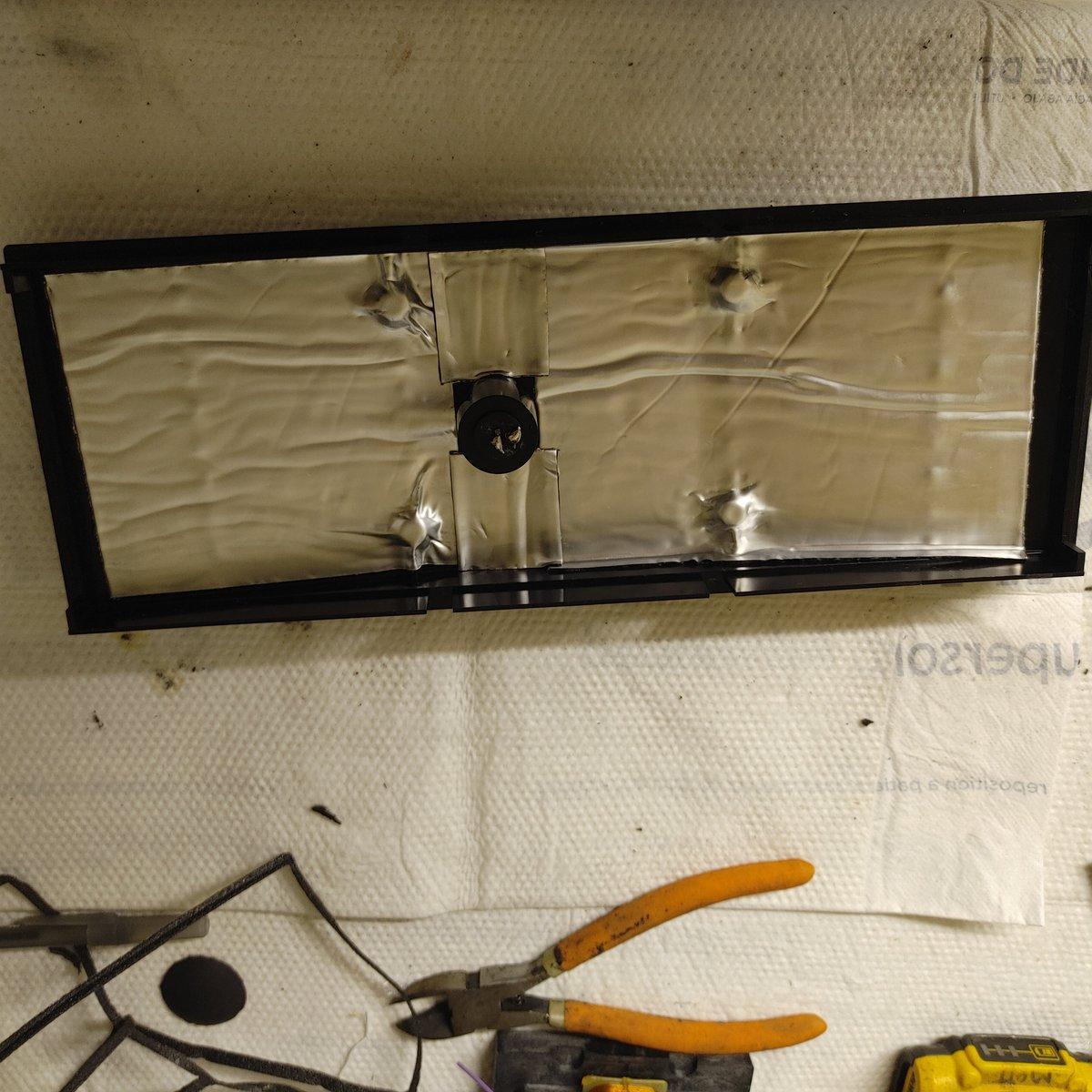

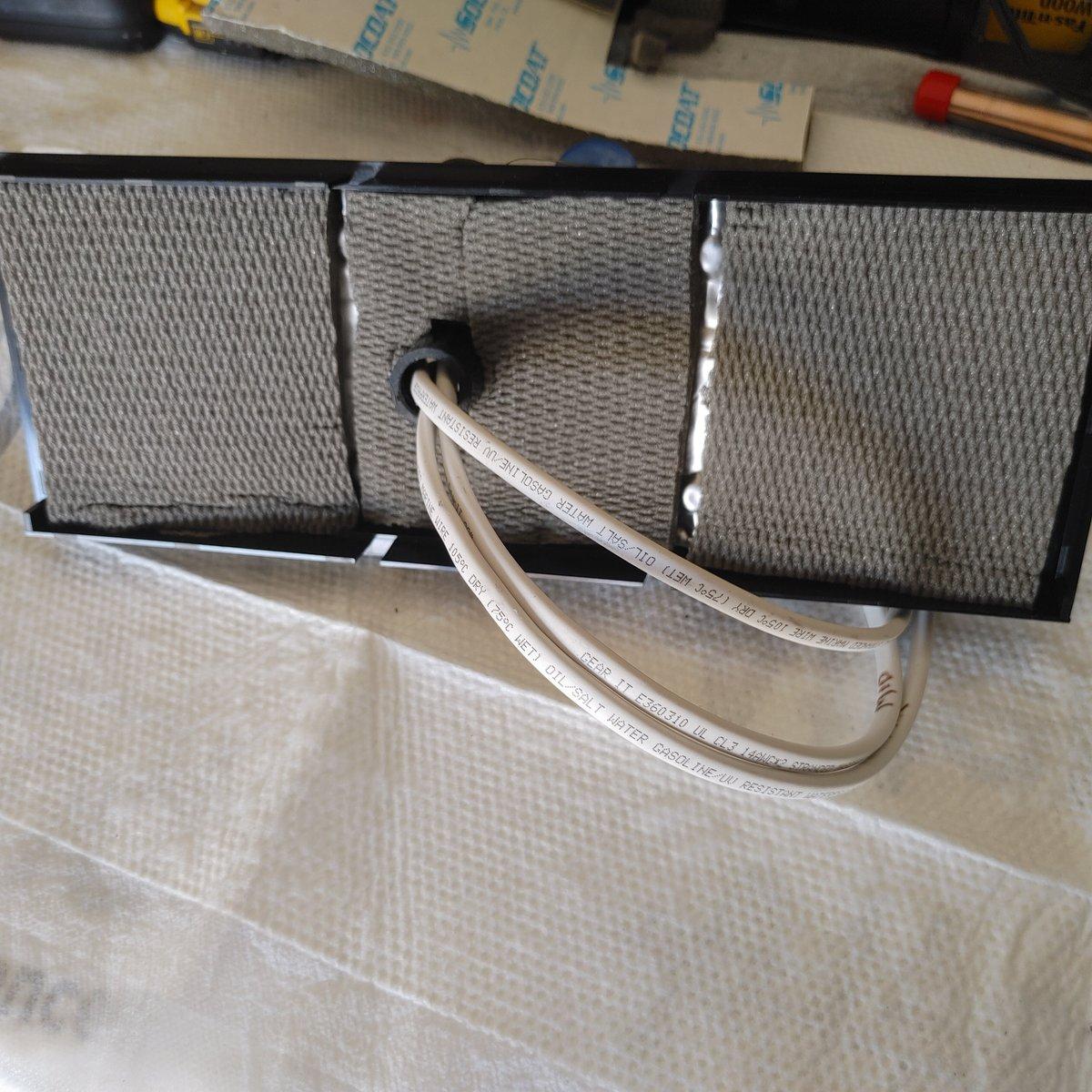

11 February 2024 at 01:34 #47130Found my build pics in those units to show a modification not mentioned previously to dampen the stamped-steel basket frames. Having done this to many other drivers with stamped steel baskets, I followed suit with fiber-reinforced butyl rubber gaskets and high density polyurethane rubber adhesives. This negates the ringing/resonance from the frames as well…

11 February 2024 at 01:47 #47126

11 February 2024 at 01:47 #47126My only values are what hits my ears.

I have phase-plugged many different midrange drivers and foam-frame quite a few brands also, mainly vintage Polk. Many others have followed suit ad I plugged and foamed a multitude of Polk drivers for many vintage Polk owners. You can read about what phase plugs do to mitigate the drivers’ cross cone frequency cancellation/destruction. Voices, cymbals and low sax for instance become more coherent by adding them. The open-cell foam inside the baskets prevent the backwaves from returning to the cones and coloring the sound.

That said, these B&O cabinets are a thinner alloy and took too a few other modifications like butyl mating the interiors to ameliorate the last bit of cabinet resonances I was hearing/experiencing. I also added a5/8″ layer of open-cell foam on the back walls to nix any errant backwave. The combination is now contributing to the most accurate signal possible eminating from the transducers.

On recommendation from another CX100 owner I removed the factory tweeter’ s phase cup and machined a slightly wider profile billet alloy ring to the throat for wider dispersion… I also added real lamb’s wool to lower it’s FS and melt with the midrange that much better. I Am very happy I did so…

11 February 2024 at 02:03 #47127

11 February 2024 at 02:03 #47127

11 February 2024 at 05:47 #47131

11 February 2024 at 05:47 #47131“I just touched up the metal of the drivers with a black marker as they will be playing with (freshly washed) frets.”

I have to ask what is a “fret”? I am currently looking for a set of C75’s to rebuild as well. I see they don’t have the mid-drivers angled like the CX100’s.

11 February 2024 at 06:52 #47132Hello xschop, with frets I meant the cloth covered plastic speaker fronts. Nothing much to mod there I guess :-). Best of luck, regards, Johan

11 February 2024 at 07:06 #47133Hello xschop, with frets I meant the cloth covered plastic speaker fronts. Nothing much to mod there I guess :-). Best of luck, regards, Johan

Ah, ok. In my neck of the woods they’re called grills. Makes sense.

I really like the look of the brushed-alloy finish of the C75’s.

A good question for the engineers is what specific alloy was used for the panels and what technique was employed to weld them together?

I have worked with many different alloys and these alloy cabinets are top quality. Kudos to B&O.

- AuthorPosts

- You must be logged in to reply to this topic.