- This topic has 85 replies, 9 voices, and was last updated 8 months, 4 weeks ago by

Evan.

- AuthorPosts

- 29 March 2024 at 06:07 #47924

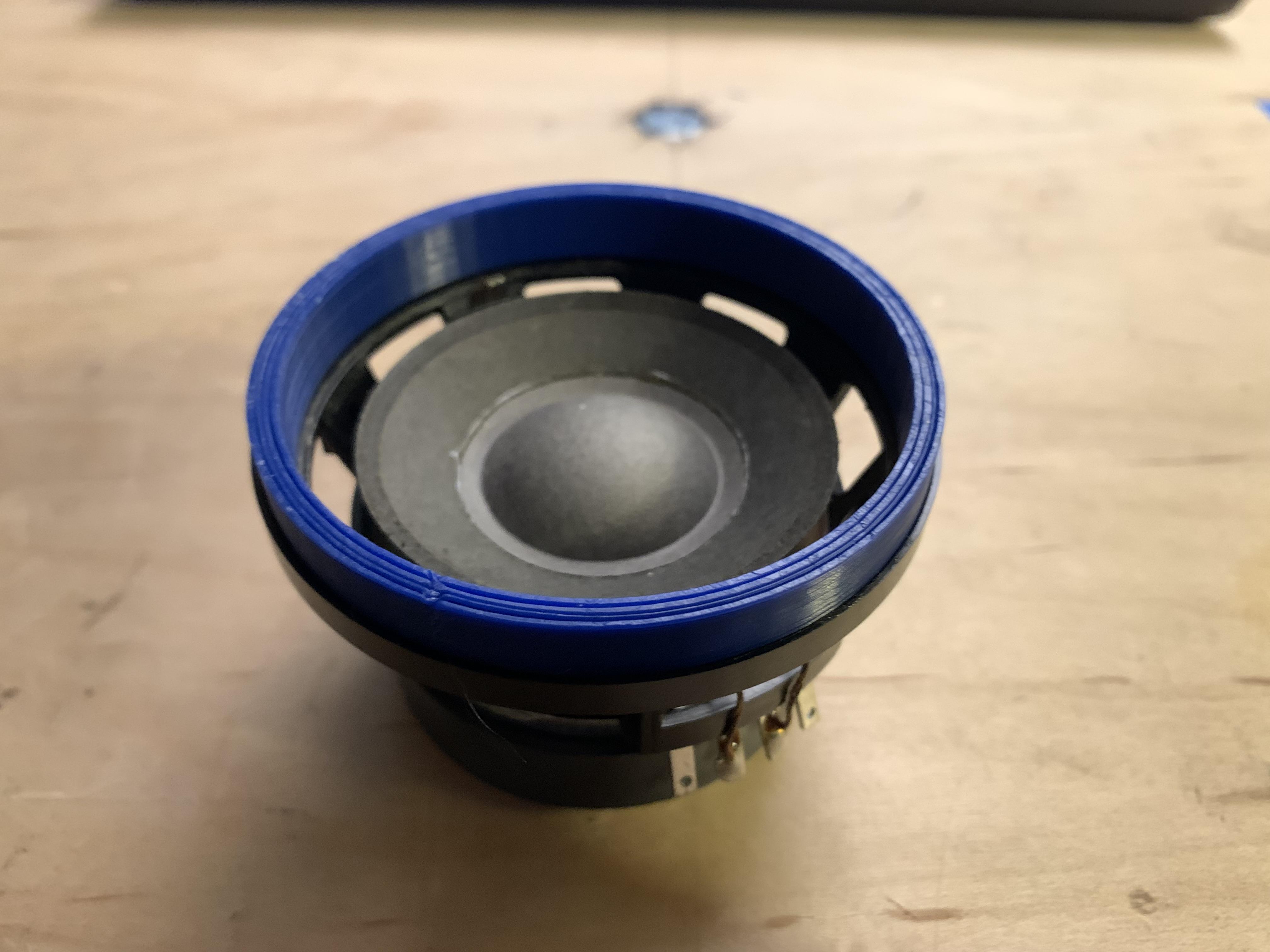

A semi-relevant example for you all: The dust cap isn’t the most critical part of the speaker (acoustically) but you can see here how different drivers can be when they are hand built.

29 March 2024 at 06:12 #47925

29 March 2024 at 06:12 #47925I picked up my first batch of surrounds from the post office yesterday. Getting close to putting these midranges back together.

The last time I did this, I had a hard time finding a way to hold the outer flange down on the basket so I printed some rings to give me the ability to press down consistently around the glue joint.

30 March 2024 at 05:02 #47926

30 March 2024 at 05:02 #47926Evan,

I use something similar to clamp the surround. Depending on the particular driver, I’ll run some tests with just the clamp. Once I’m happy with the performance, the surround gets some glue. Sometimes, a segmented clamp is needed so that the surround can be glued a section at a time with a thin needle applicator syringe.

I’m not too surprised to hear that much of this is being done by hand. I’m guessing that the difference between the higher and lesser quality parts has to do with the “end of line” testing and sorting.

Glitch

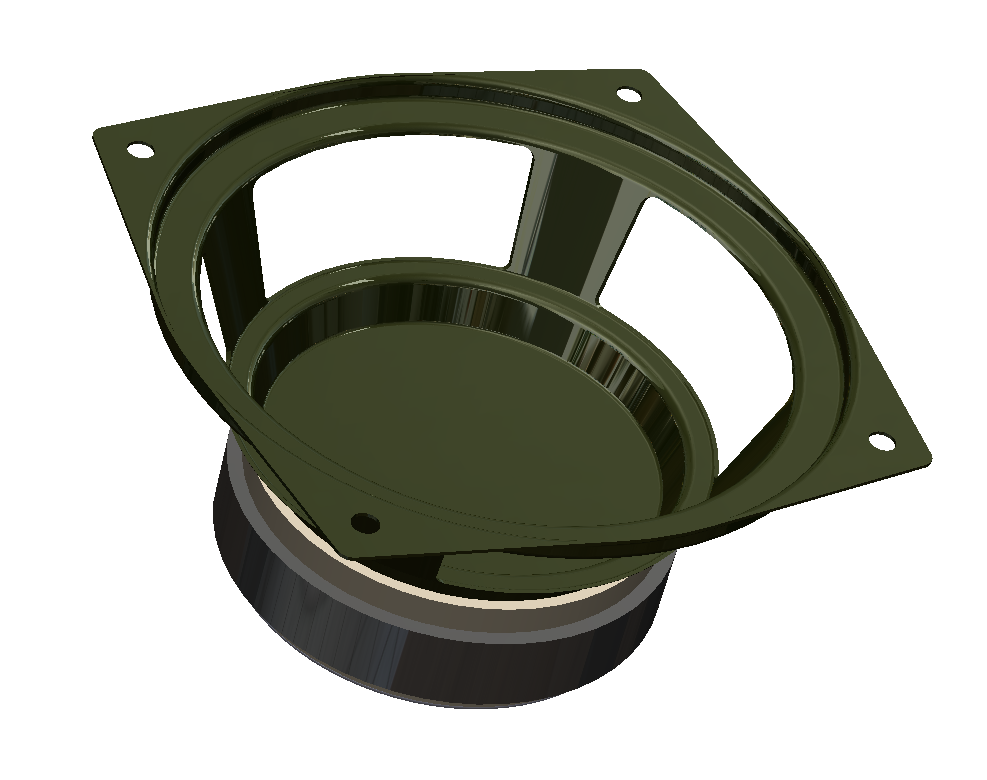

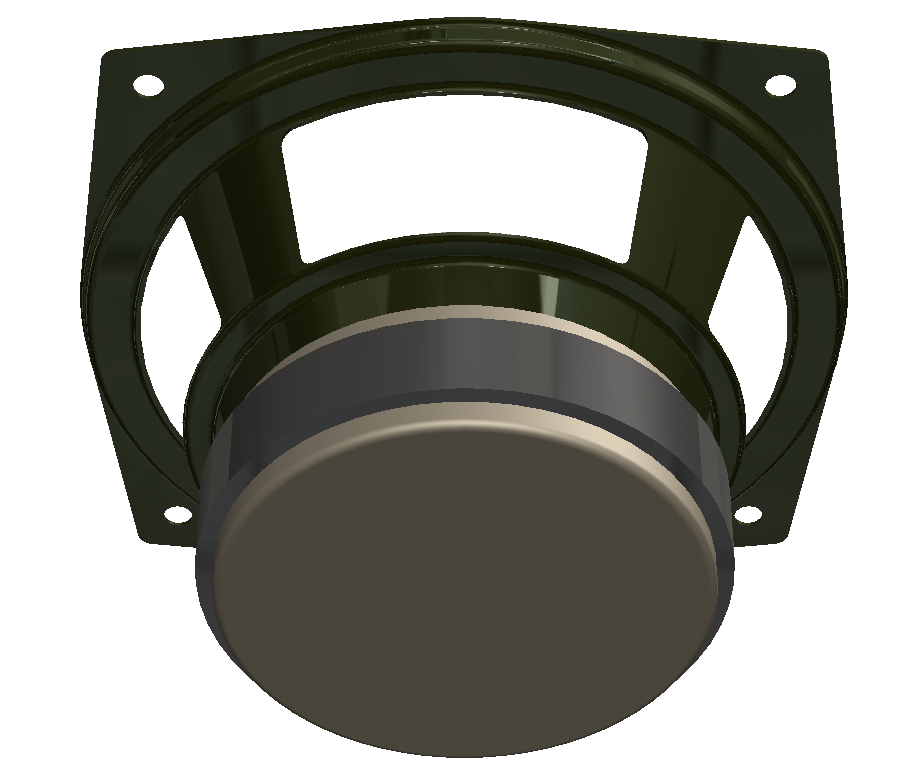

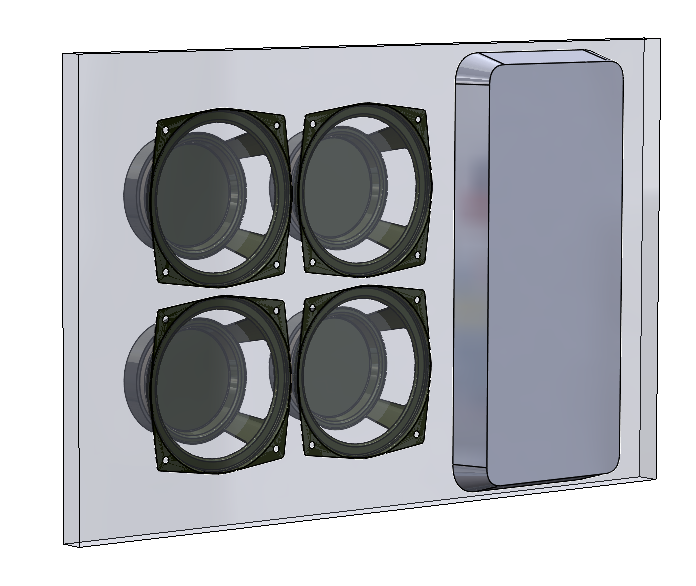

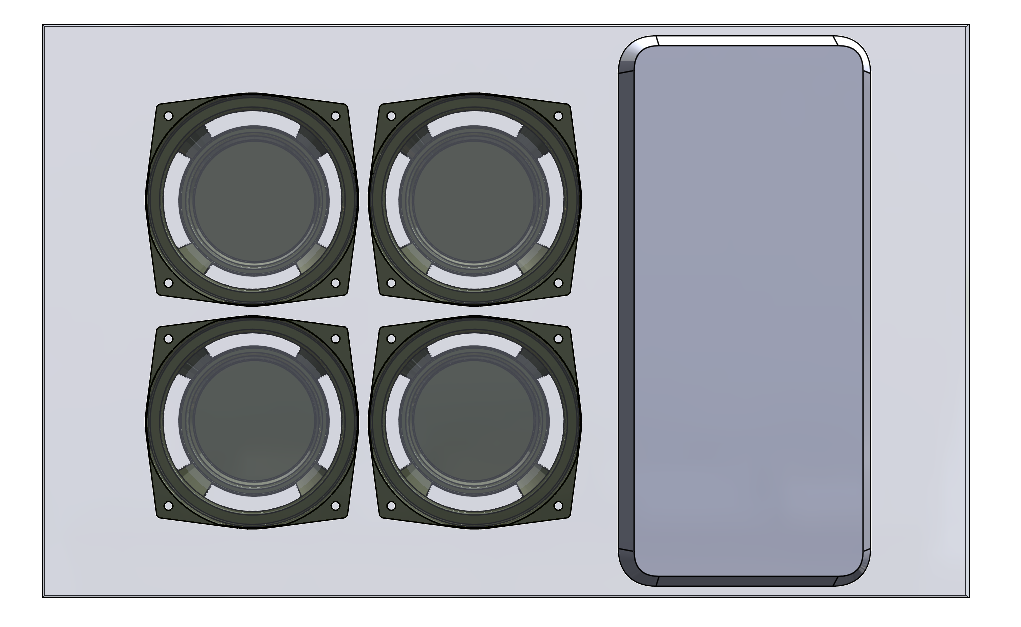

1 April 2024 at 11:17 #47927Finished modeling the woofer (basket and motor) so I can begin to design them into a baffle. Most importantly I tried my best to capture the basket’s very poor brownish-green e-coat finish 😛

1 April 2024 at 11:22 #47928

1 April 2024 at 11:22 #47928Evan, I use something similar to clamp the surround. Depending on the particular driver, I’ll run some tests with just the clamp. Once I’m happy with the performance, the surround gets some glue. Sometimes, a segmented clamp is needed so that the surround can be glued a section at a time with a thin needle applicator syringe. I’m not too surprised to hear that much of this is being done by hand. I’m guessing that the difference between the higher and lesser quality parts has to do with the “end of line” testing and sorting. Glitch

Indeed. End-of-line testing is paramount. From what I hear, 100% of parts are gauged by this process.

Thanks for the tips! I am considering doing something similar, my colleagues are highly recommending I just go all-in and remove the dust cap and do it properly. Beginning to lean in this direction but I have so many of these things to do!

2 April 2024 at 03:42 #47930I am considering doing something similar, my colleagues are highly recommending I just go all-in and remove the dust cap and do it properly.

I always consider the likelihood that I could remove the dustcap and residual glue without damaging the cone. Finding a suitable replacement dustcap is sometimes a problem. I like to install a slightly larger dustcap than what I removed to help hide any evidence that the driver was worked on. This is usually pretty straightforward with woofers, but I’m not so confident with something like a Penta midrange.

Another thing to consider with dustcap removal and shimming is that uneven tension of the surround/spider will undo any shim alignment as soon as the shims are removed. Obviously, drivers with tighter tolerances will be more sensitive to things like this.

One idea that I’ve had is to use a combination of techniques. Combine the segmented clamp/gluing concept with using an inspection scope (stereo microscope) to visually check the coil alignment. I haven’t tried this yet, but will when I have the need to service something that requires high precision.

Glitch

2 April 2024 at 05:35 #47931I’m getting into this now! The twee-mid baffle is starting to take shape and I’m definitely going to be printing my own instead of carrying over the original module from the Penta. For many reasons related to design, color (will be printed in color) and geometry in general.

2 April 2024 at 12:05 #47929

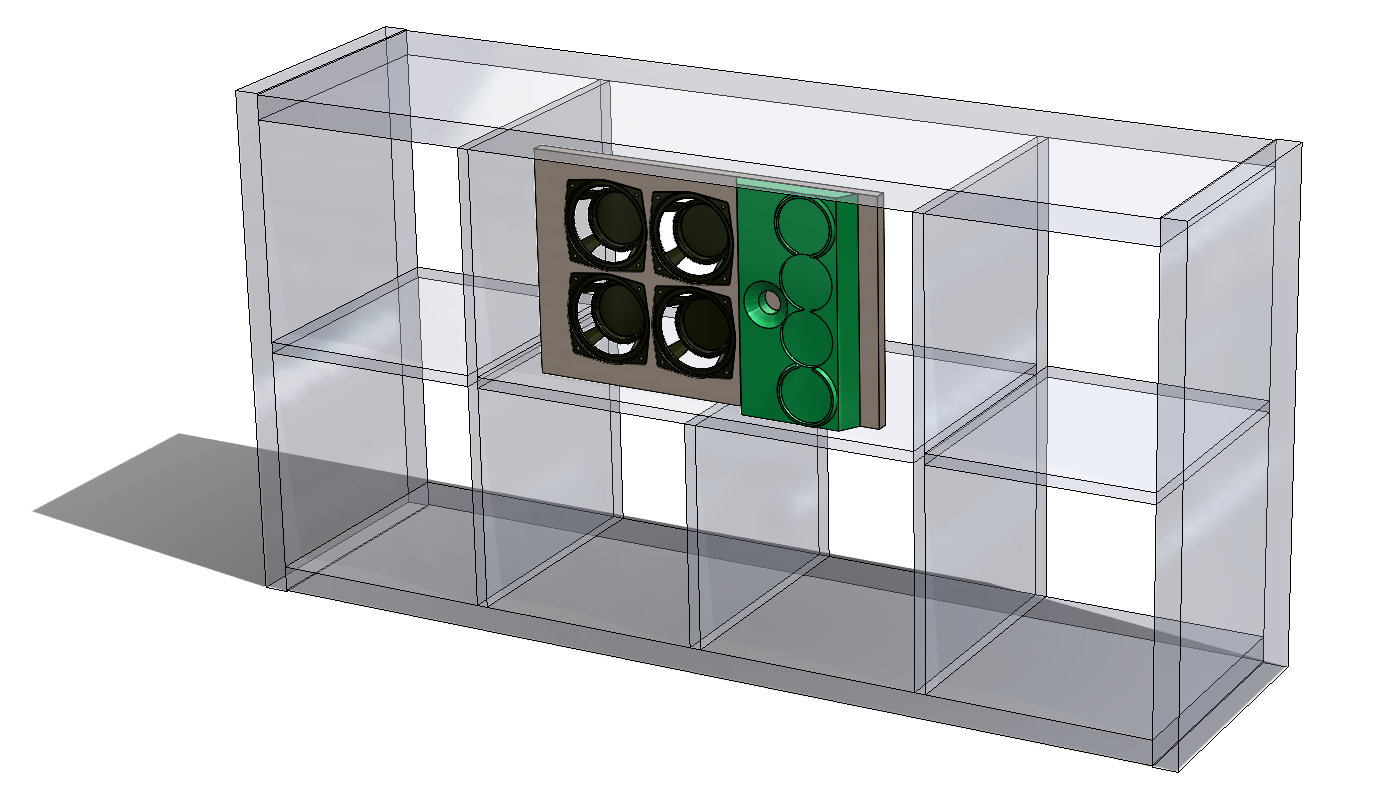

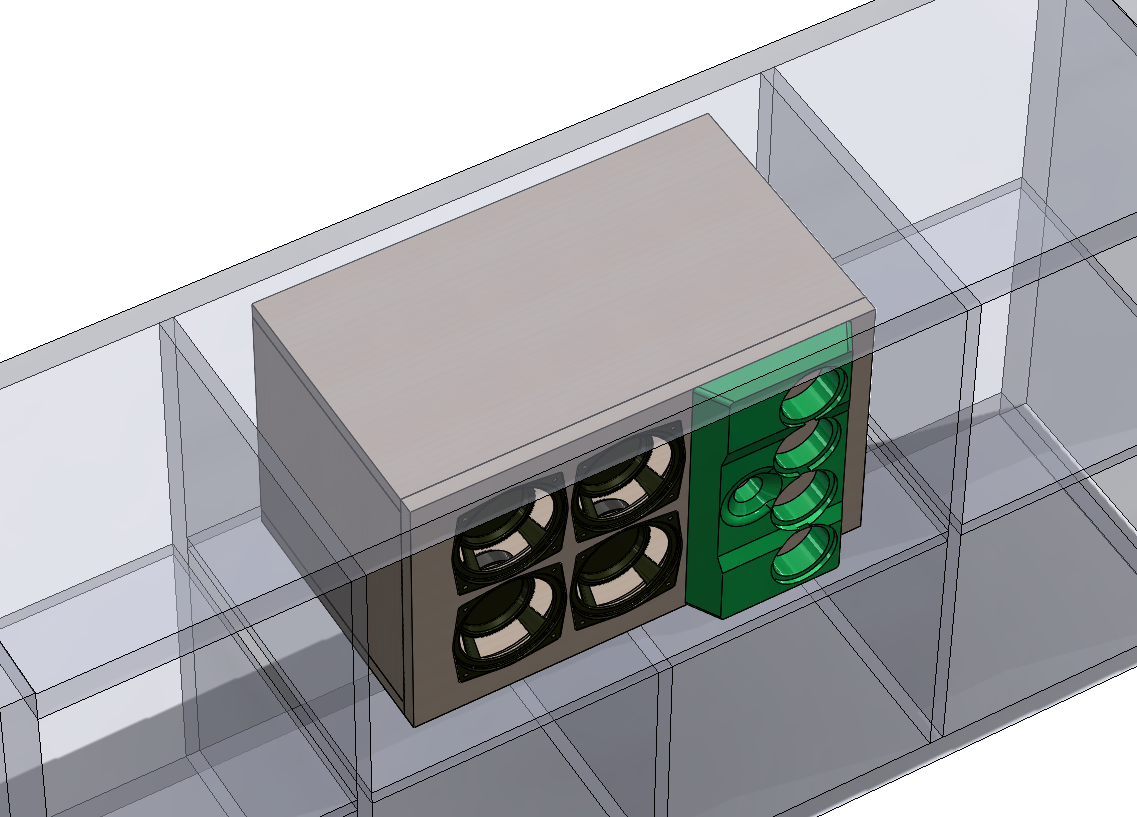

2 April 2024 at 12:05 #47929A quick sketch after drafting in a basic twee-mid baffle to start to package everything. Interestingly I had planned in my head that the twee-mid baffle would live on top of the main baffle surface but in reality the pentas see a baffle step in the other direction (duh). May have to rise the woofers up to match. We will see.

Also contemplating printing my own twee-mid chassis as the original is just so hard to seal. Has very thin geometries at various points and is pretty ugly if left uncovered.

This baffle uses a golden ratio factor but the long axis of the twee-mid module seems to be dominating the baffle shape. Tons of space left over around the woofers. This would be good if I planned on keeping the ports but right now I am planning on ditching them, this is plan of record right now but subject to change once I get into some simulations and measurements.

3 April 2024 at 04:03 #47935

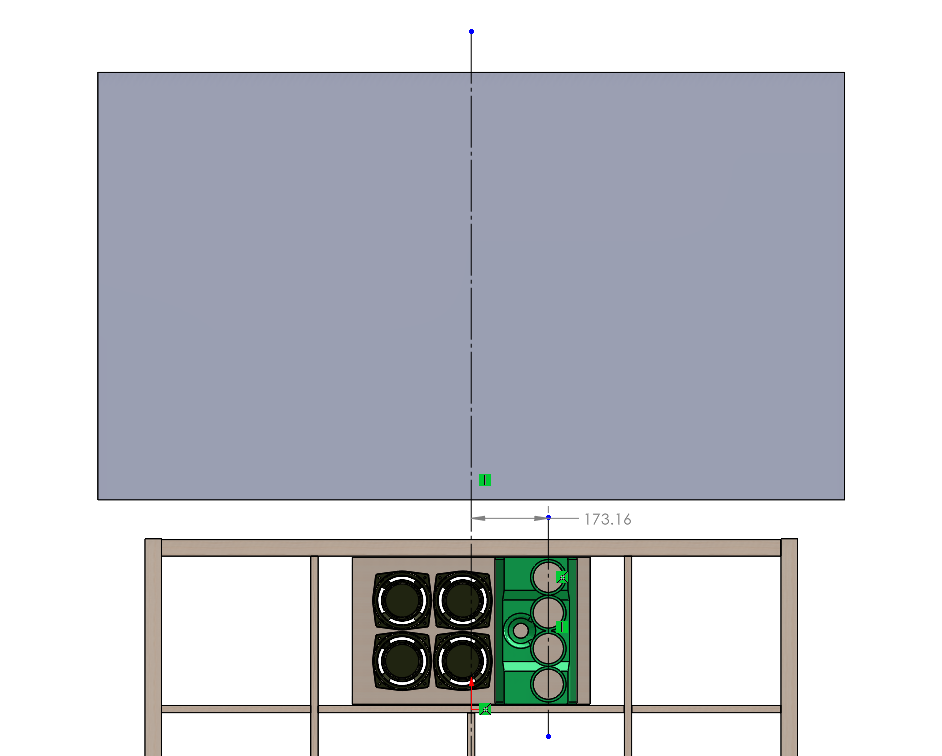

3 April 2024 at 04:03 #47935The woofers are placed together in order to reduce any comb filtering. I don’t currently have a bunch of off-axis listening positions in the room yet but we are still decorating and the couch is about to be swapped out for a much larger one where one might be seated very far off axis.

I did a quick sketch showing the current alignment. Currently the midrange array is only 173mm off axis. The listening/viewing distance is quite long (I’ll measure it later) so I don’t think this misalignment is significant at the moment.

I should add, my TV is quite large – 75 inch nominal size.

3 April 2024 at 06:52 #47932

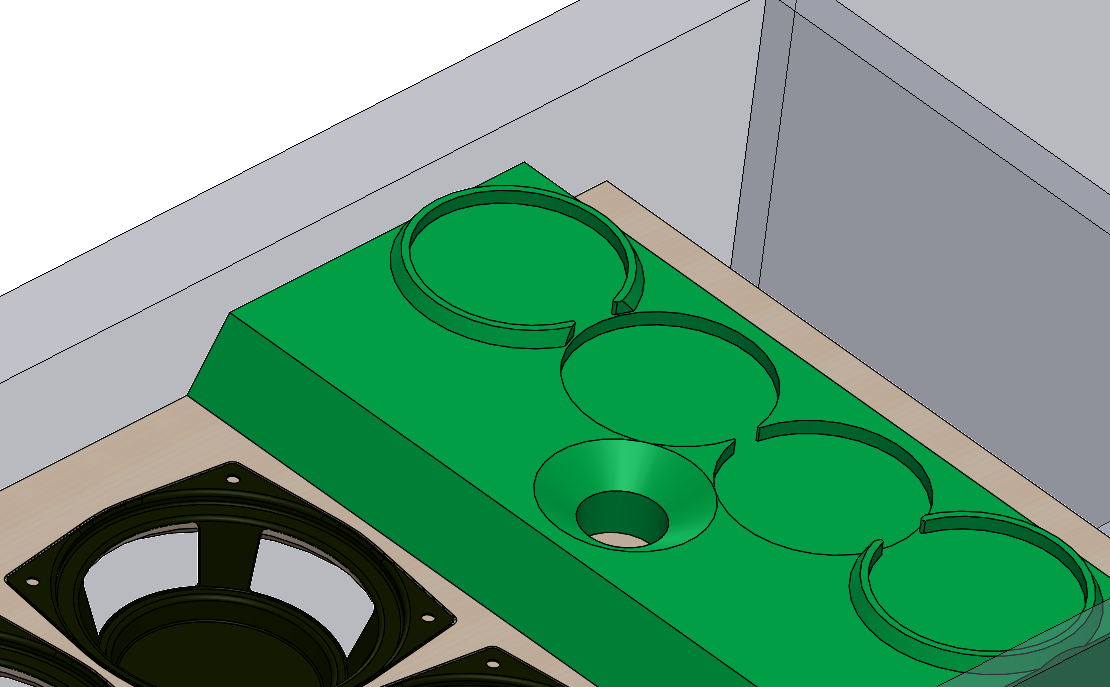

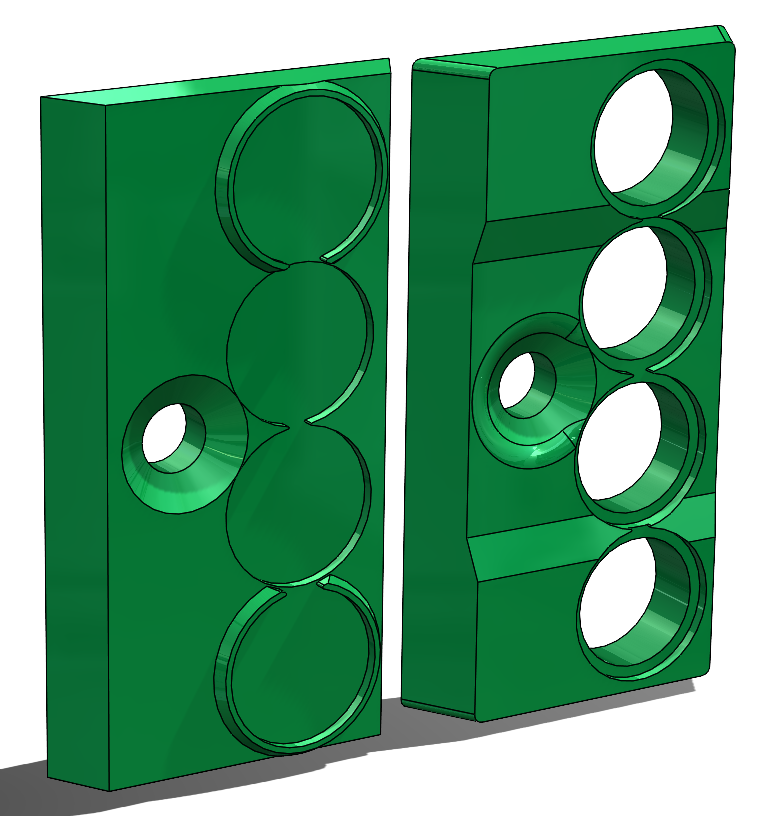

3 April 2024 at 06:52 #47932Really didn’t like the look of the thin chamfered ring elements on the two outer most midranges. I lifted these, roughly, from the original tweemid module.

Decided to redesign the whole module with a bit more of an integrated appearance in the surfacing department. Still working out some details but this new version seems easier on the eyes.

3 April 2024 at 07:09 #47933

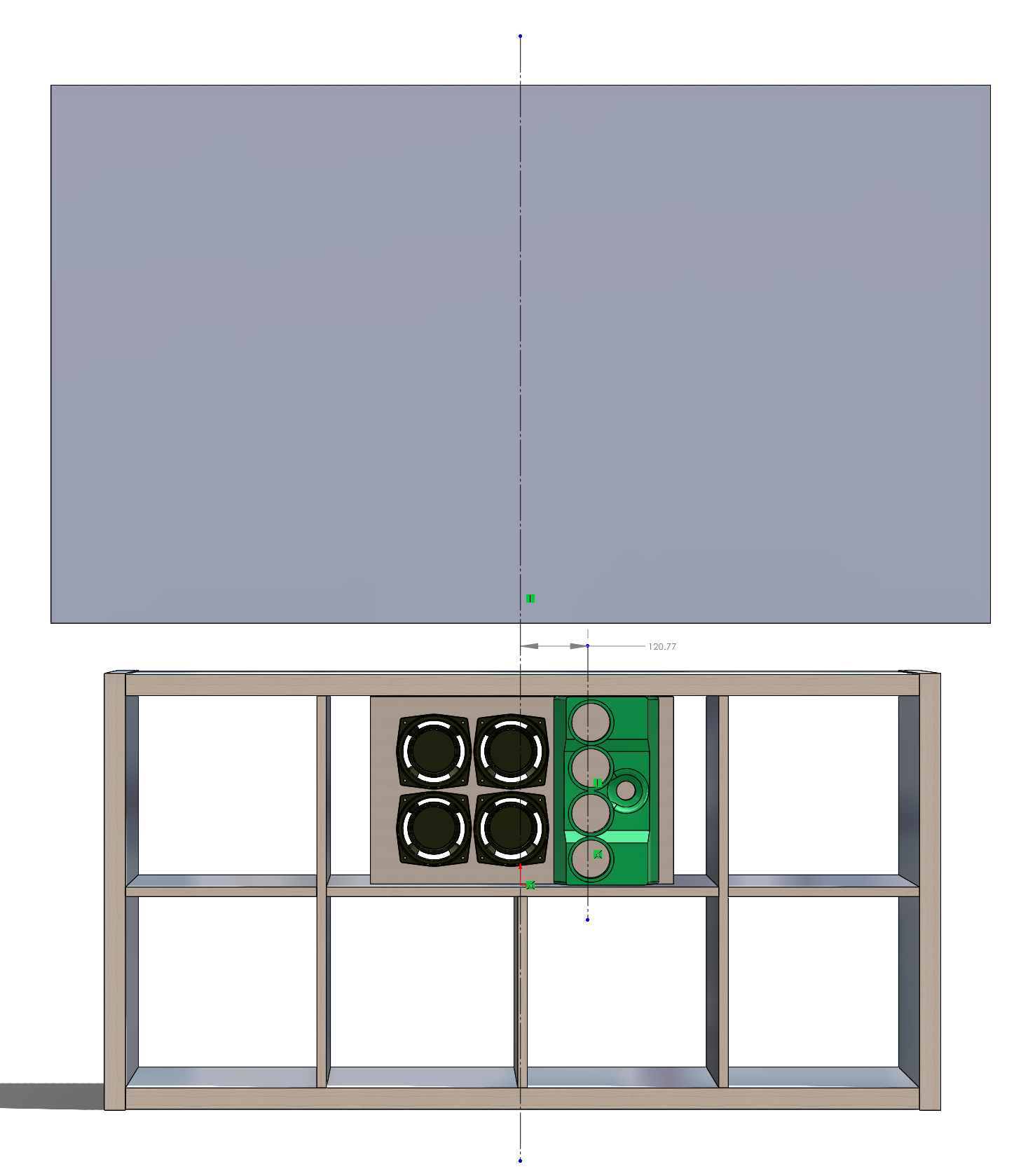

3 April 2024 at 07:09 #47933First sketch of the box. Plenty of room to spare, inside volume is 43L at the moment. According the BeoWorld the Penta has a “net volume of 32L”.

Not including the tweemid sticking out, the box dimensions are 534W*319L*330H. It will shrink in the next few iterations as I learn more about the original but I’d love to hear if it should morph one way or the other proportionally (for non Ikea Kallax applications for example).

3 April 2024 at 09:51 #47934

3 April 2024 at 09:51 #47934Make it more symmetric, move 2 of the woofers to the other side.

The ear can locate the higher frequencies and the mids pretty good. Lower are nor quite so important, the ear does not locate a subwoover.

But the woofers are not subs. You will hear, that he voice of a news reporter does not come from the TV, but somewhere else. With this design, the news reporter is always sitting on the right side, not in the middle.

It will be very strange, when symmetry is missing and the origin of a voice is located in different locations. And it will differ when a man is speaking or a woman.

It is also very important, from which hight you hear the voice. Because of that soundbars are so popular. Slim under the TV, as near as possible to the screen. It is irritating when the voice comes not from the screen, but to far under the TV.

3 April 2024 at 10:47 #47936Flipping the tweemid module over I can get that misalignment to 120-ish mm. Seems pretty reasonably to me.

Also I recently learned that the crossovers are 700Hz and 3kHz. 700Hz is pretty high (for voice) so the 2×2 woofer config is here to stay I think.

4 April 2024 at 06:06 #47937

4 April 2024 at 06:06 #47937Make it more symmetric, move 2 of the woofers to the other side.

If this is of interest, to anyone reading this, I will offer this design configuration separately.

7 May 2024 at 01:33 #55337Well everyone, lots of random updates for you since BeoWorld went dark during the transition to the new forum so here goes….

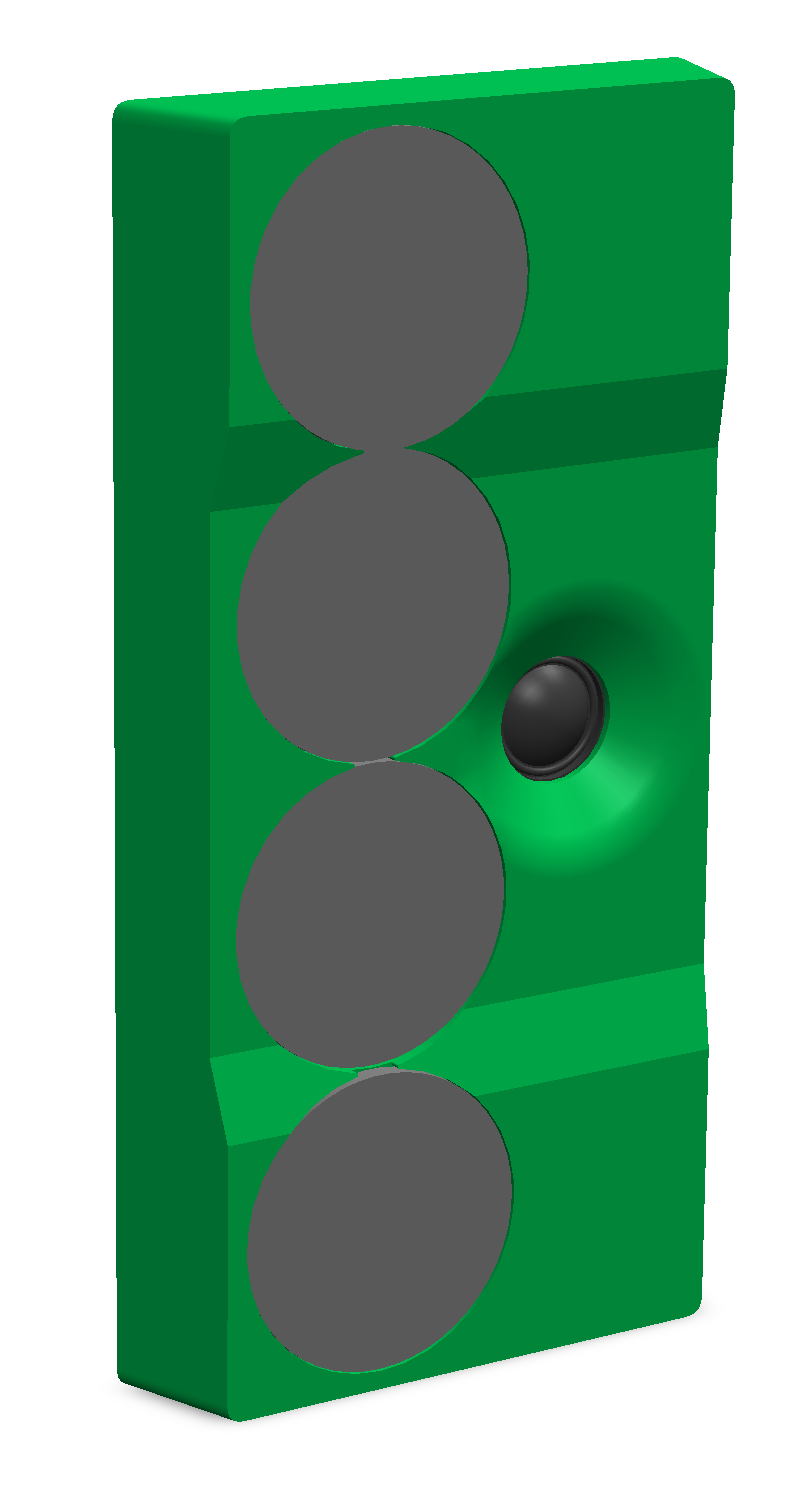

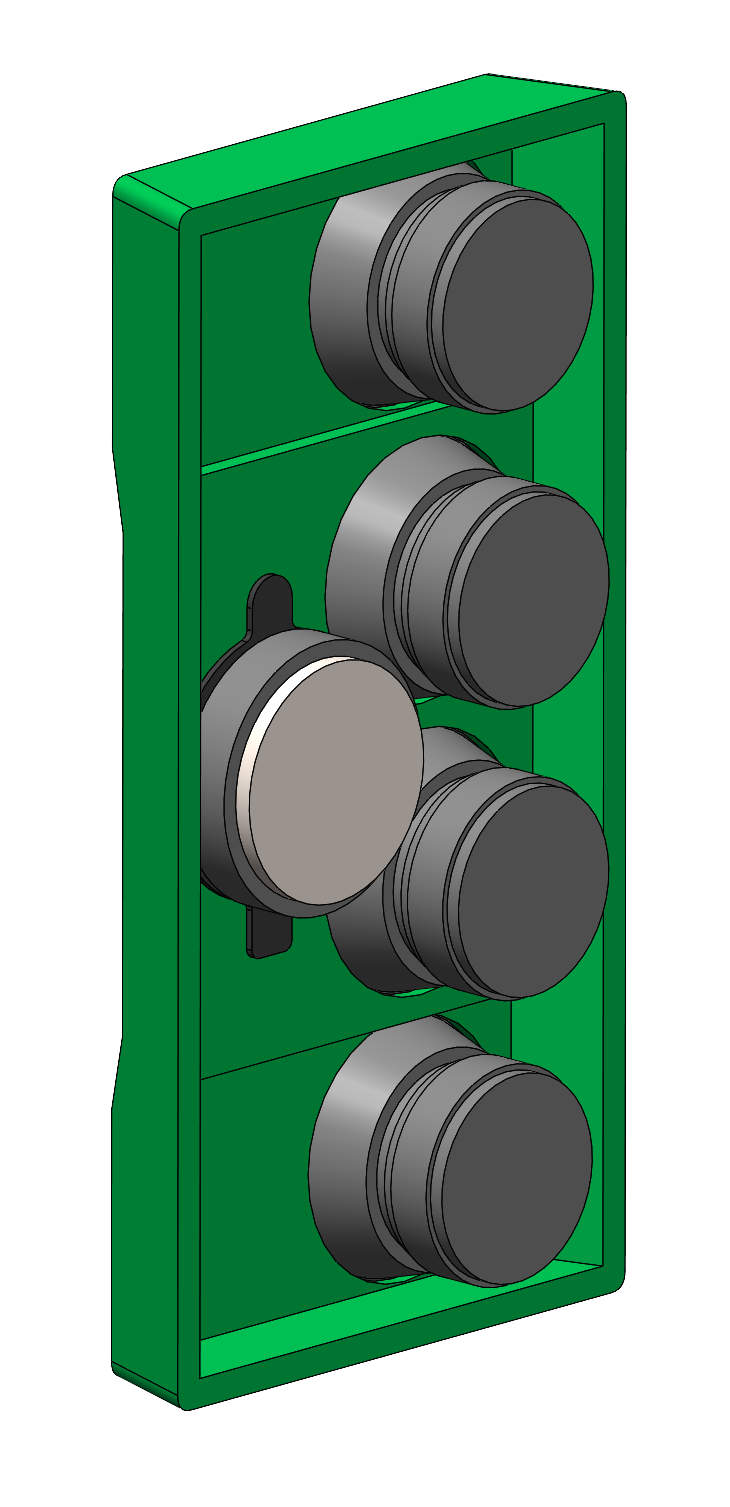

First up is the updates on the twee mid module – slowly getting the module modeled up. Had to model the tweeter and now all that’s left is to get the bosses and fixings modeled in so I can take it for a test print.

7 May 2024 at 01:36 #55338

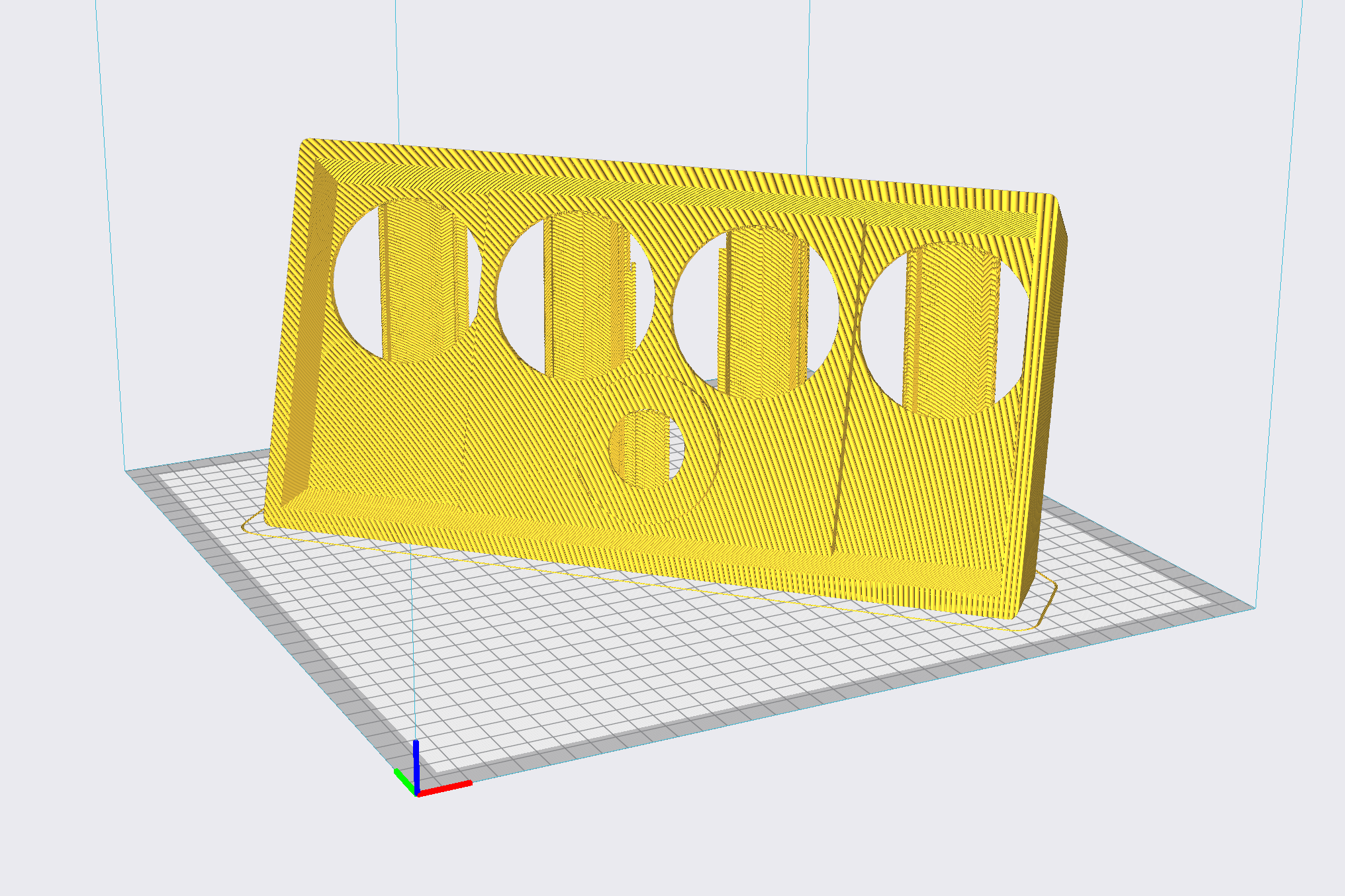

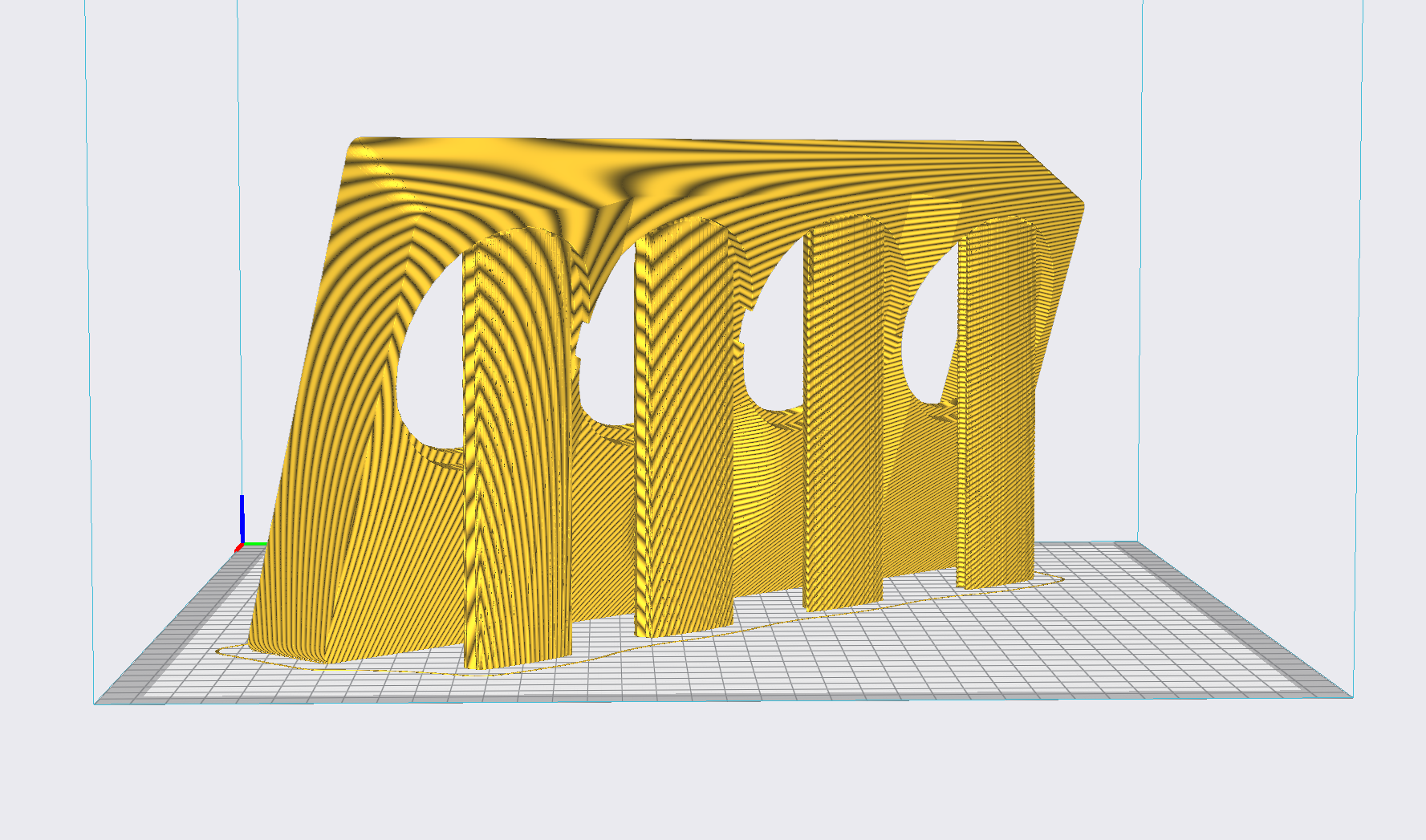

7 May 2024 at 01:36 #55338Speaking of printing, here are the first goes at attempting an orientation for a build on an FDM style machine.

Sadly my Ender 5 Plus is currently down for repairs but I’ll be running a test soon. Currently sliced at 0.25mm layer and 0.4mm nozzle for now. Might bump the nozzle up after the machine repair but haven’t decided yet. Currently at 36hr print time with healthy build parameters for strength!

7 May 2024 at 01:45 #55339

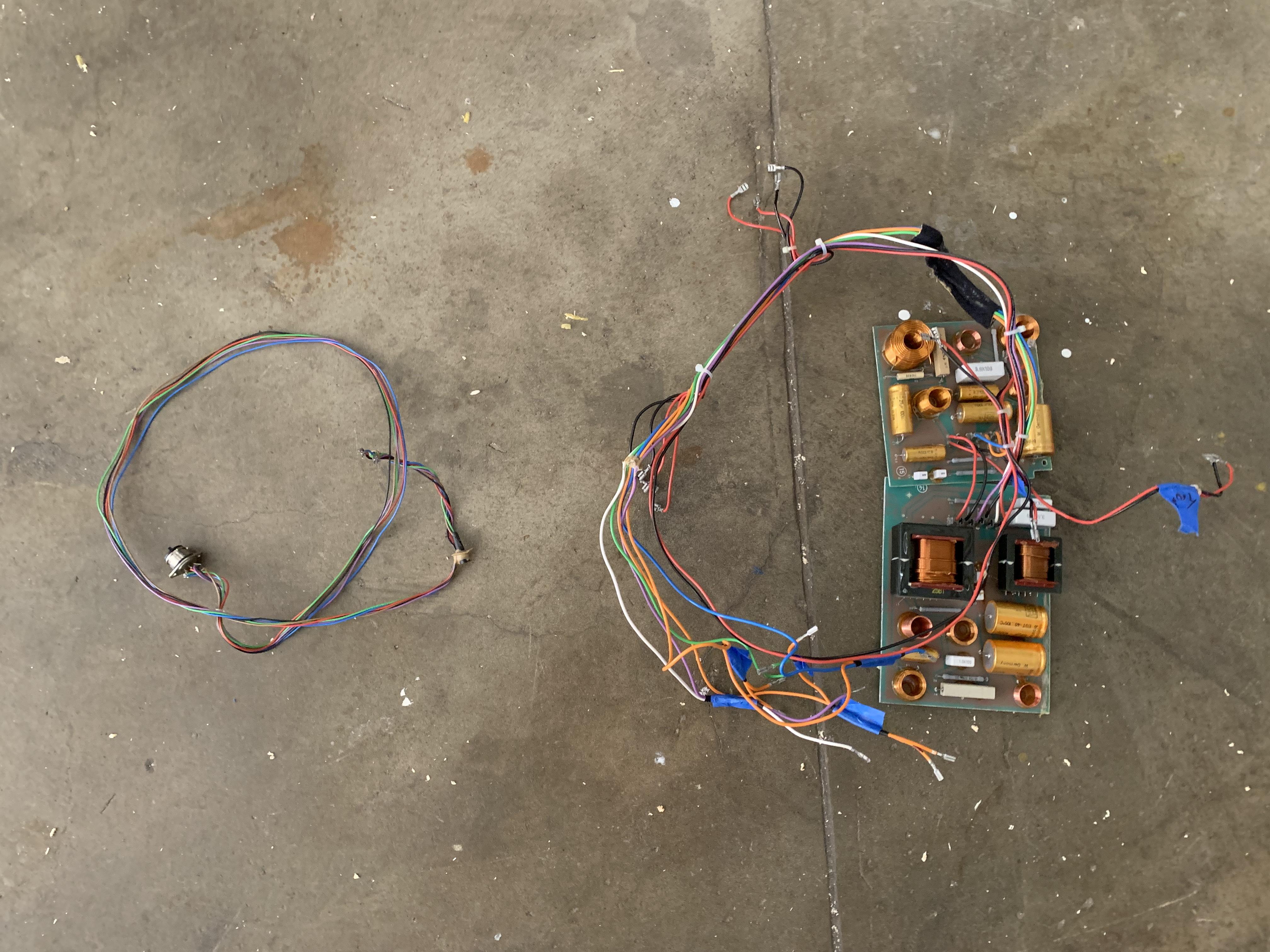

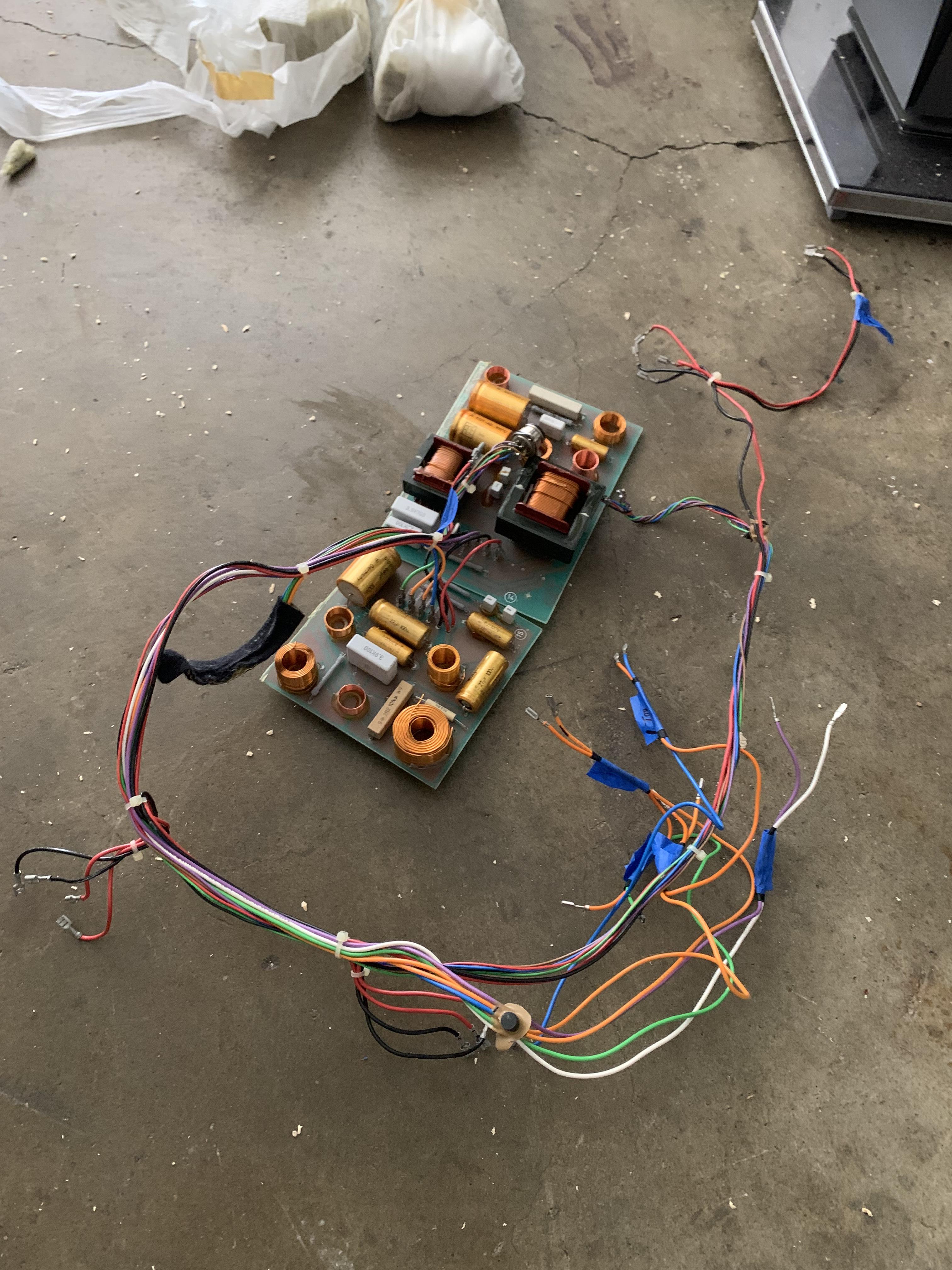

7 May 2024 at 01:45 #55339Lastly is the progress on the teardown of the donor speaker. I have finally de-wired the cabinet and pulled the stuffing out.

Of course the crossover and wiring harness will get reused but we need to get the cabinet empty in order to reverse engineer the volume. Stay tuned for this!

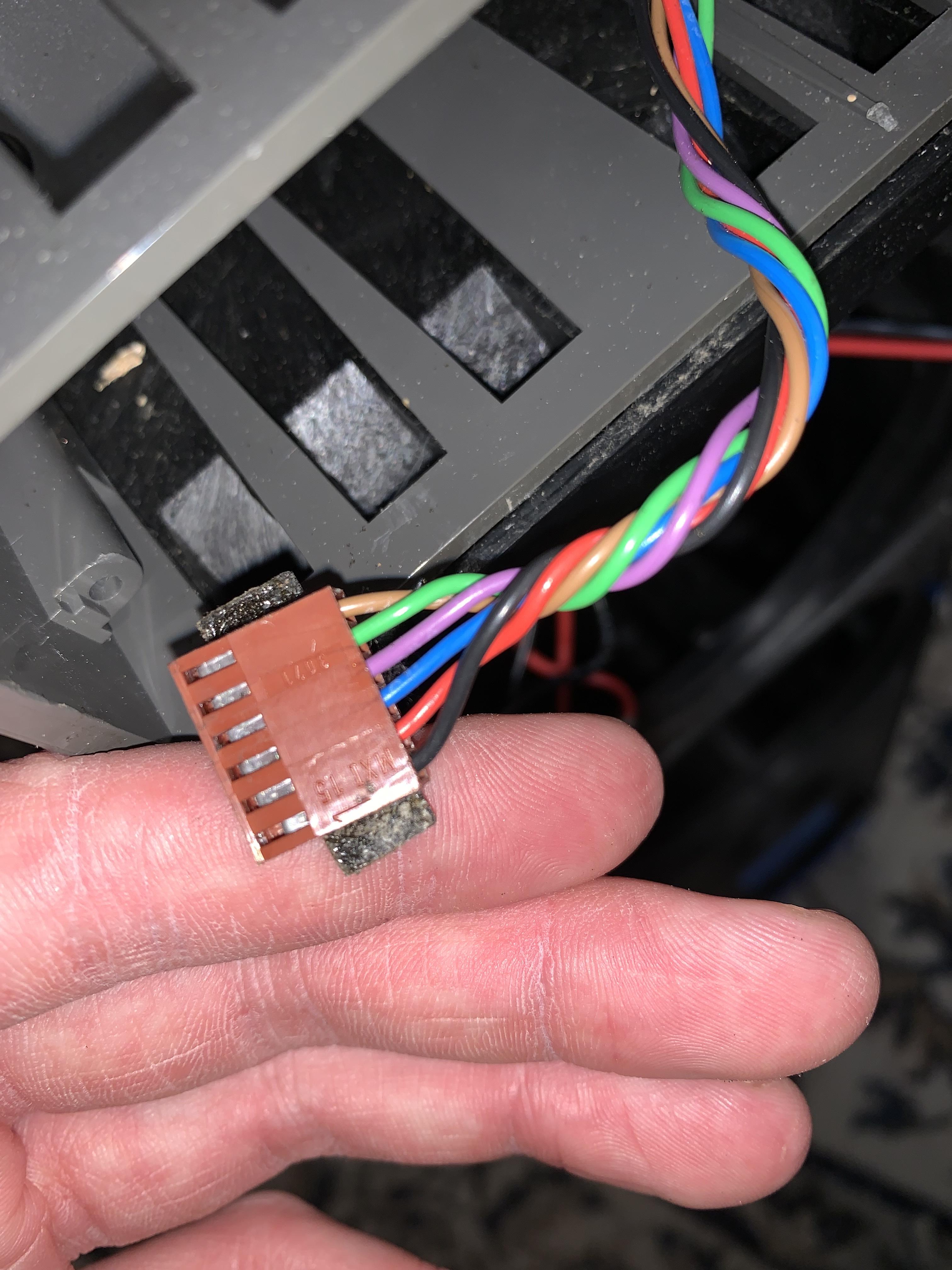

De-pinned the display connector in order to pull the cables back through the baffle.

Making sure everything gets labeled before I forget where everything goes! Pictures (and other Pentas) will serve as back up resources haha.

Slowly easing out the stuck-in crossover boards.

Separating the display harness from the speaker harness (no need for it here, at least this time around).

What the full harness looks together (speaker and display harness combined, as it is built in the speakers).

7 May 2024 at 22:35 #55356

7 May 2024 at 22:35 #55356Ok everybody, the moment has finally arrived. Time to tackle the silliest task of this project! Its time to measure the internal volume of the cabinet.

The dry weight is 9kg.

Usually when reverse engineering speakers, the office gang and I use uncooked beans of some kind. This time we decided to use water.

7 May 2024 at 22:42 #55357

Here goes nothing! The thought of becoming “that guy” who filled a penta with water was starting to sink in haha.

7 May 2024 at 22:47 #55358

After a few minutes of filling we started to notice some spots that were leaking. This expected but I did miss some big ones – I forgot to patch the pass-throughs for the tweemids and the display. So pause and go for a reset! The grass around the office could use it honestly.

- AuthorPosts

- You must be logged in to reply to this topic.