- This topic has 4 replies, 3 voices, and was last updated 10 months, 1 week ago by

Glitch.

- AuthorPosts

- 10 April 2024 at 06:40 #54189

I’m finishing up one of my winter projects, a Beosystem 5500. Everything was either free or cheap due to being broken or partially working. The project started with a free Master Control Panel 5500 and a “for shipping cost” Beomaster 5500 (thanks again Evan) and evolved from there. I had a lot of fun doing this and learned much in the process.

Beomaster 5500

- Reflowed solder joints

- Repaired cracked circuit board

- New capacitors, trim pots, relays, thermal compound

- WIMA caps and updated OPAMPS for preamp

- New trim panel and chassis feet

- Detailed cleaning inside and out

- Adjusted per service manual

Beogram 5500

- Reflowed solder joints

- Full (disassemble) cleaning and lubrication

- New capacitors

- New rubber parts: platter belt, sliding chassis belt

- New trim panel, chassis feet and lid bumpers

- Detailed cleaning inside and out

- Polish dust cover, replace lid damping grease

- Adjusted per service manual

- New SMMC3

Beogram CD 5500

- Reflowed solder joints

- Repaired laser assembly and deep clean

- New capacitors

- New rubber parts: tray belt

- New trim panel and chassis feet

- Detailed cleaning inside and out

- Adjusted per service manual

Beocord 5500

- Reflowed solder joints

- Repaired power supply

- Repaired tape transport

- Tape transport – Full (disassemble) cleaning and lubrication

- New capacitors, trim pots, thermal compound

- New rubber parts: drive belt, pinch rollers, drawer belt, drawer rollers

- New NOS main drive motor, hot oil vacuum infused bearings

- New board mounting clips

- New trim panel and chassis feet

- Detailed cleaning inside and out

- Adjusted per service manual

MCP 5500 #1

- Repair corroded traces on circuit board

- Disassemble and clean switch pads

- New capacitors

MCP 5500 #2

- Replace bad transistors

- Disassemble and clean switch pads

- New capacitors

Audio Terminal

- Repair corrosion in battery compartment

- Clean switches

Random observations

- Rolling OPAMPs in the preamp wasn’t fruitful. I could not hear or measure any meaningful difference between the original and a variety of modern chips.

- Acquiring the test/calibration tapes was harder (and more expensive) than fixing the tape deck

- Repairing/restoring something after a botched repair attempt is harder than fixing something that failed due to natural causes. I already knew this, but the tape deck reaffirmed this.

- Restoration parts can cost more than the acquisition price of a component

- One can still put together a very nice, vintage B&O Beosystem from scratch with patience and perseverance.

TODO

- Find a solution to the cable mess behind the Beosystem stack.

- Fix the Beogram chatter problem (mentioned in another thread).

- Continue verifying that the system meets the original performance specifications.

I assume that a restored Beosystem 5500 is not noteworthy to most forum members. For the couple of other people that might be interested, I’ll happily provide any additional information/pictures.

Glitch

12 April 2024 at 03:40 #54190That is an impressive list and job Glitch. A very timeless and complete set in my eyes.

This set is what my father in law bought new (with BV Pentas) and got me infected with the virus! He still has the speakers, but I just replaced the BM5500 with a BeoPlay Connection Hub + BeoLink Passive. To use the plastic Samsung TV remote (yuk). He clearly got cured.

13 April 2024 at 03:35 #54191A very timeless and complete set in my eyes.

Thank you for the kind words.

I think that the styling of the 5500-7000 series has aged quite well. One of my goals is to get B&O equipment into the “public rooms” at my son’s house. My daughter-in-law can be pretty selective about the decor. So far, she has only agreed to a Stage, but I think she is warming up to other options.

It must be hard to go back to a lightweight plastic remote after getting used to a Audio/Video/AV terminal.

Glitch

15 April 2024 at 09:01 #54192Hey Glitch – congrats on such an awesome result!

Great project and I’m glad that BeoMaster ended up working out for you. I guess the temp issues ended up getting solved with your overhaul? Last time I used it it was just scorching hot to the touch even when in stand by.

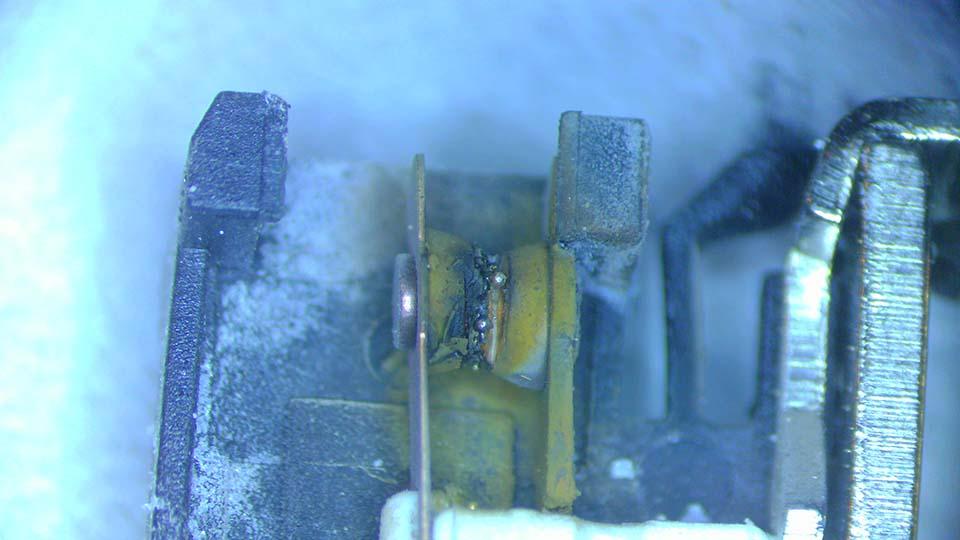

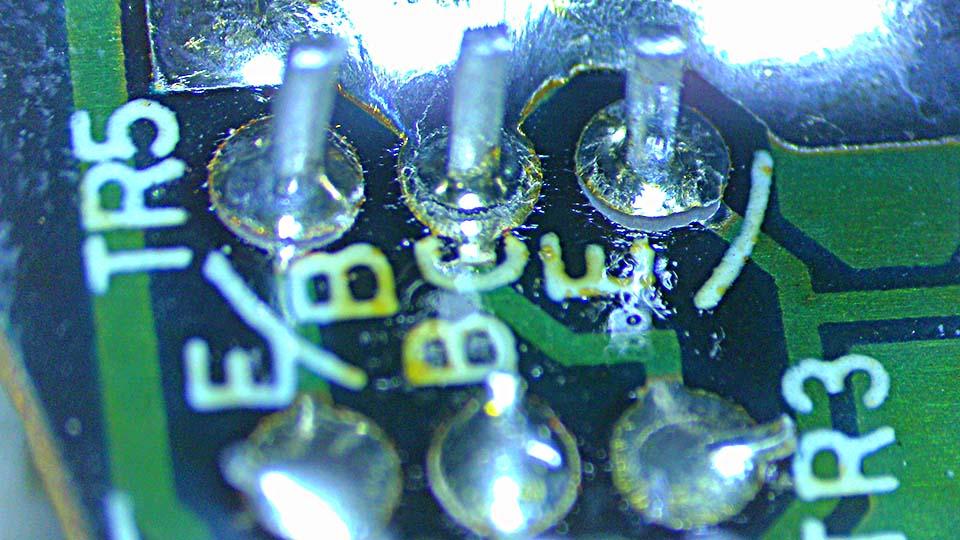

16 April 2024 at 02:48 #54193I didn’t find a specific reason for the overheating. The first step of this Beomaster repair was to remove the circuit boards and inspect them under a stereo microscope. I like to make repairs to any “mechanical issues” (i.e. cold/cracked solder joints, cracked boards, solder bridges, etc.) before applying power for the first time. I recall fixing what appeared to be shipping damage, but my notes are sketchy. Unfortunately, the quantity/quality of my note-taking can be inversely proportional to my excitement about working on something and I was pretty stoked about digging into the project. 😉

I did take a few pictures of the more interesting discoveries.

Power relay contacts

Broken solder pads on fan control board.

The Beomaster is running at “as expected” temperatures. Warm, but not hot enough for the cooling fan to engage.

Glitch

- AuthorPosts

- You must be logged in to reply to this topic.