- This topic has 8 replies, 4 voices, and was last updated 2 years, 4 months ago by

Glitch.

- AuthorPosts

- 17 October 2022 at 09:37 #39951

Hey guys,

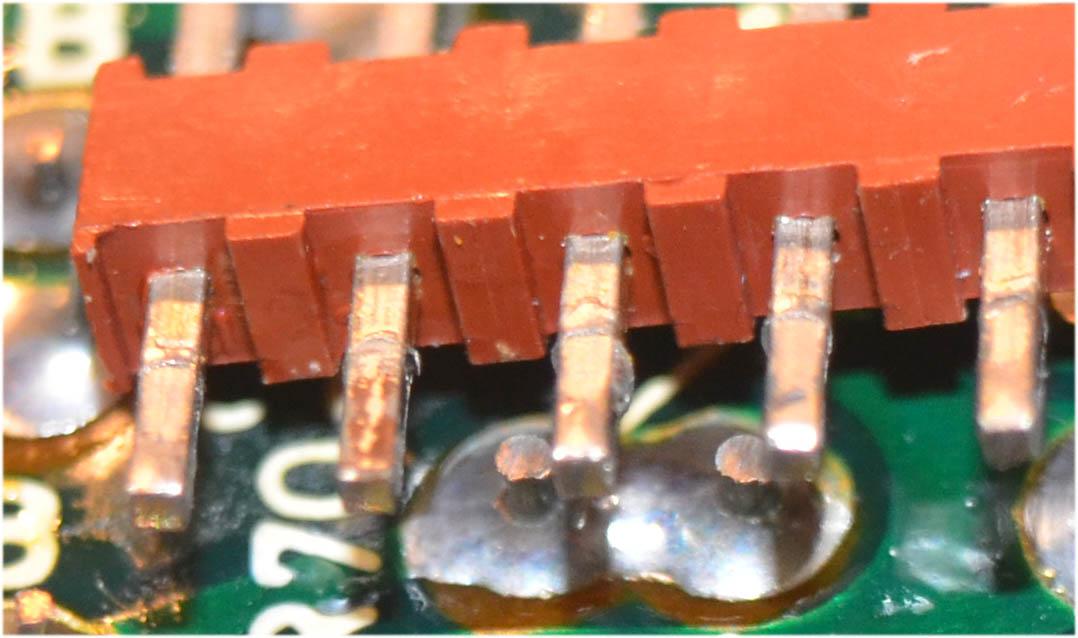

I’m trying to identify a part on my beomaster 1700. It’s the pin headers (P4) that looks like standard 2.54 mm connectors, but are actually bigger. I think they’re about 4.2mm but not 100% sure. I’m struggling to find a replacement

It was causing an intermittent crackling issue (I think) and had some rust on it. I’ve sanded the rust off, but I’m worried it’s going to come back now that I’ve pulled the plating off

18 October 2022 at 03:23 #39954Cheers guys, I’ve sprayed some of this on, https://www.jaycar.co.nz/contact-cleaner-lubricant-spray-can/p/NA1012

I guess worst case, we’ll see if the crackling comes back

18 October 2022 at 03:33 #39955If the contacts plating has gone, the connector is pretty much worthless.

Looks like the connector on the tonecontrol module – right?

Is it “only” the male part that has lost its plating or also the female part on the “piggy-back” PCB?Martin

18 October 2022 at 09:07 #39956I think the female connector is ok, I tried to take a photo with an Allan key opening the connector, and as far as I can tell it looks clean inside

Yes it’s the connector that the tone control daughter board sits on. I have had the amp for around a year and have very slowly been trying to fix a crackling issue that I isolated to happen when I wiggle the tone control board (I actually thought it was the connector for the wires to the board (p3), so I replaced it, but it wasn’t that). If I had the amp “open” i.e. on its little bonnet stand, it wouldn’t crackle too much, but if I closed it, it would crackle. I’m guessing the different angle was shifting how the board was putting pressure on the connector.

Cleaning it up definitely seems to have made most the crackling disappear, so big improvement.

18 October 2022 at 12:04 #39952Quite frankly as long as the female connector is also clean, I would not worry about it coming back. You likely didn’t have rust but oxidation and the connections should be fine.

18 October 2022 at 12:30 #39953The best and most reliable option is to replace the connectors. However, you will likely be fine with just protecting the newly cleaned connector so it doesn’t re-oxidize quickly.

A light coating of Deoxit is most likely all you need. Any light oil would also work in a pinch.

Another option is to “tin” the connectors with a very light coating of solder. If the pins are brass, this is quite easy to do.

I would start with one of the above options, then if the issue returns, go though the trouble of replacing the connectors.

Glitch

19 October 2022 at 04:21 #39957You should also reflow the connector’s solder joints as these are notorious for developing fractured connections.

19 October 2022 at 10:46 #39958Thanks Mark, I did that this morning, (and trying not to speak too soon, because I keep thinking I’ve fixed it and then it comes back the next day), it seems to have gotten rid of all remaining crackling!

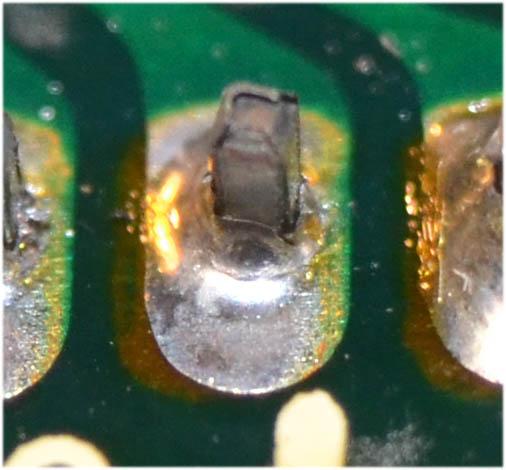

19 October 2022 at 11:11 #39959Very close inspection of the connector pins is recommended. The attached picture is of the board side of a connector. The solder holding the connector to the board was actually fine, but the plating came loose from the pins. You can see some corrosion on the raw metal of the pins (second pin from the left was worst). Just reflowing the solder on this connector probably would not have resulted in a long term fix.

Here is what the solder joint looked like…

Glitch

- AuthorPosts

- You must be logged in to reply to this topic.