- This topic has 3 replies, 2 voices, and was last updated 2 years, 2 months ago by

Llurkio.

- AuthorPosts

- 3 December 2022 at 10:41 #41267

Hello All,

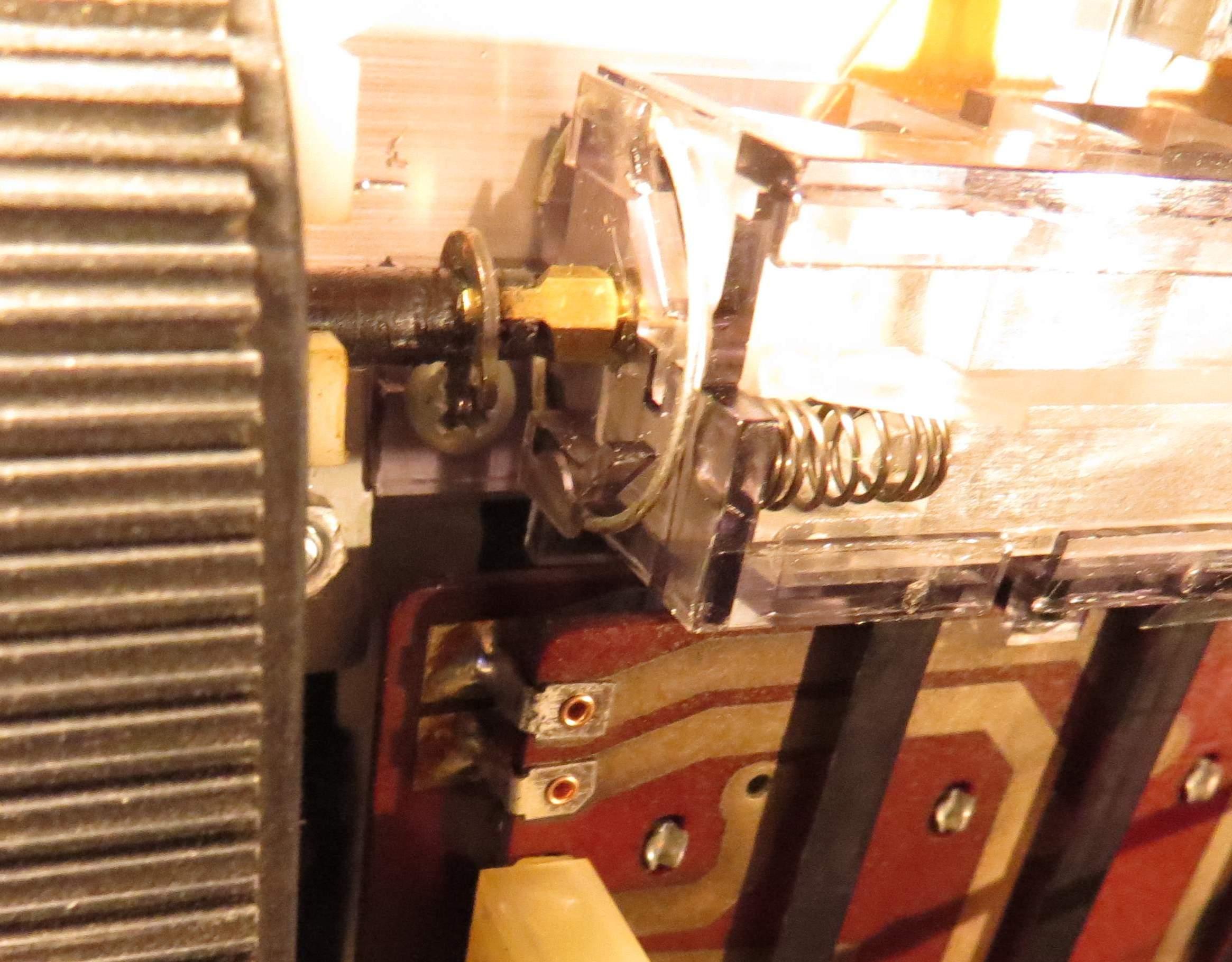

I have a Beomaster 1600 with the “tractor tread” belts on it that is in really, really great shape. Except the belts are pretty much shot and of the 4 drive wheels, only one has a slot that will drive a shaft. Unfortunately someone already switched the position of the wheels at some point because of the broken slots. Has anyone tried 3D printing something like a drive wheel before? Also a long time ago someone had posted in the forum that a timing belt from a car would work for the belt replacement. But I could never find which belt that might be.

Any thoughts or help would be appreciated. Ironically the receiver still works and probably should have the capacitors replaced, but if I can’t resolve the mechanical issues there doesn’t seem to be much point.

Regards,

John

14 December 2022 at 10:43 #41268Hi John

As there’s been no suggestions for you, I’ll try to offer my thoughts.

I’ve done a couple of these and luckily mine didn’t have your problems (mine was clutches), so would it possible to glue some tight fitting plastic pipe over the tractor wheel axles and pin them in place with some very hot pins pushed through ?

As for the other side, drill through the metal shaft and do the same using something like an “R” clip (removable, if needs be) ?

I really don’t know if this is a practical solution, but I’d be looking at something along these lines initially – otherwise, keep an eye open on Ebay for a scrap machine (but I suspect this might just have the same problem !)

Tim18 December 2022 at 01:32 #41269Hello Tim,

Sorry for the delay. I very much appreciate the suggestion. I have decided I will first try learning the software to design the wheels based on my 1 good one and 3D print them. I have access to a 3D printer at my university and the software for drawing it is free. I may have found a source for the belts and am waiting for that to arrive. The only other sticking point may be clutch washers. I have not checked those out. But if the 3D printing doesn’t work out I will try your suggestion. Hopefully something good will come out of this I can share with other Beomaster 1600 people.

Thanks again!

John

18 December 2022 at 12:23 #41270Hi John, yeah that sounds like a plan, I’ve not had any experience with 3D printing so I’m unsure of the integrity of the formed pieces, but the joint between the wheel axle and drive shaft is going to be quite stressed (for it’s size)- might I suggest putting a small tight circlip over the joint, I believe they came out of the factory like this.

And, if you do find a supplier of new belts, please, please let me know where you get them, one of my machines has several splits in the belt and has a piece of mylar (?) glued underneath, it works but not as smooth as I’d like.

If you’re unable to source new clutch washers, PM me.

Tim

- AuthorPosts

- You must be logged in to reply to this topic.