- This topic has 10 replies, 4 voices, and was last updated 2 years, 4 months ago by

beostuff.

- AuthorPosts

- 24 September 2022 at 05:31 #39262

I have a pit marked platter on a 4002 turntable. The only way it seems to be able to remove them is to remove the spokes and refinish the platter. Can someone give me an idea how to remove the spokes? I saw something about putting it in the oven then removing them but can’t find that link. Any ideas would be great.

Thanks

26 September 2022 at 05:36 #39264thanks. i did get the spokes off and attached it to a drill and sanded it down. Doesn’t look as good as yours tho. thanks for the info on not gluing the spokes back in – as I was about to do exactly that!

26 September 2022 at 06:47 #39265Hi

Trolle some different sandingpaper, or some Kind of sanding wool like this:

to get a smooth surface.

And try different speeds of the Drill

For clear coat take matte finish

Regards Christian

26 September 2022 at 07:58 #39263Hi

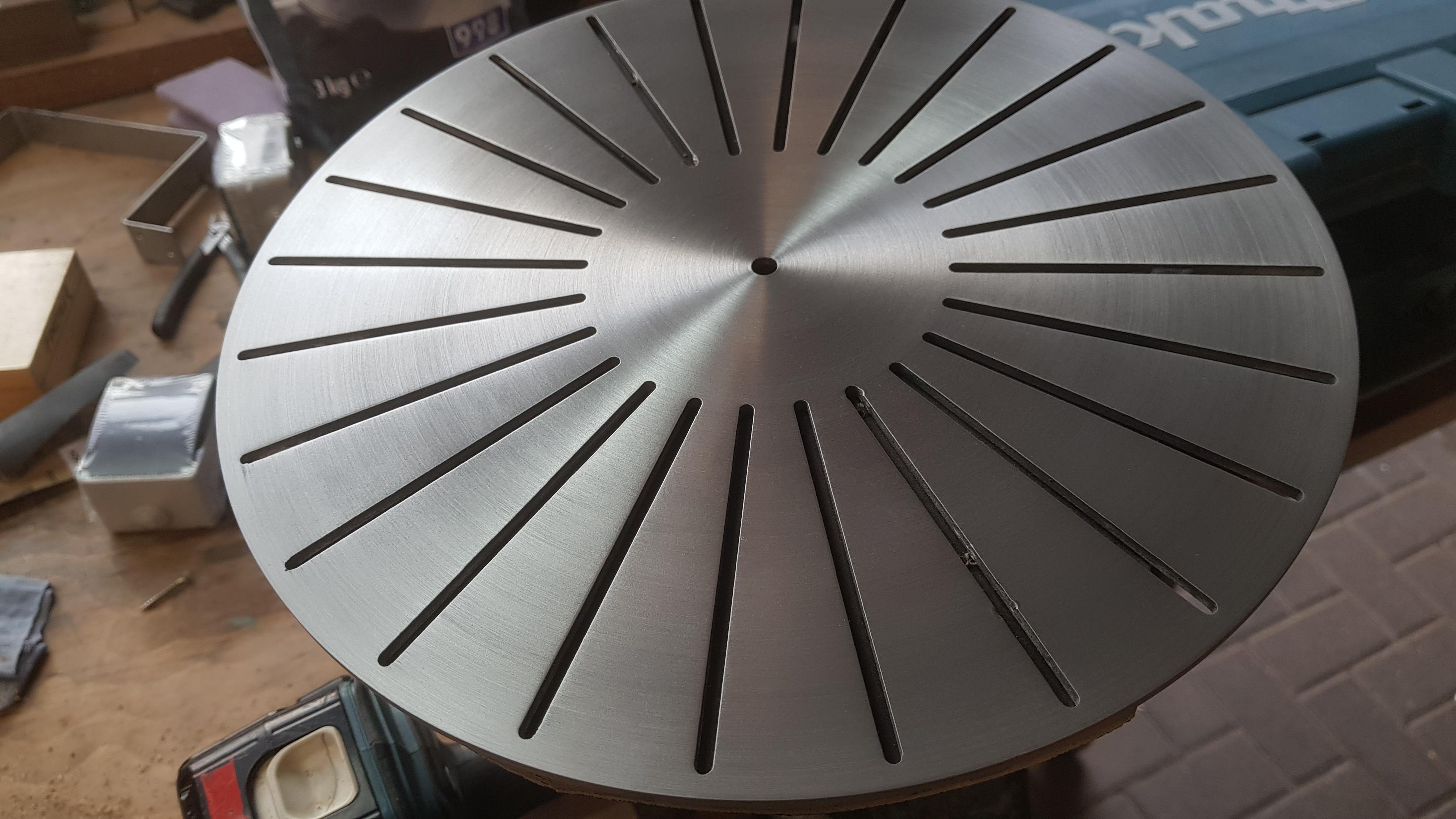

I have had a similar problem with a platter from a beogram 4xxx, sad I can´t remember which model it was.

The subplatter (where the belts runs) was not glued to the top aluminium platter with the ribs, there are some models with this seperated platters.

So the ribs are inserted from the top of the aluminium platter and melted to a nearly flat stucture at the backside of the aluminium platter.

There I cutted this melted part away and pried the the ribs out from the backside.

I sanded the platter with some 600 -800 grain paper on a cordless drill with an attached woodplate where I could fix the aluminium platter with two countersunk srews. The screws will make a little mark at the holes for the ribs but the ribs are covering this mark if you tighten the screws not to hard.

Here is a picture of the sanded platter, sadly I took only one picture

After sanding I gave it layer of clear coat and pushed back the ribs in.

They are pressed fitted and must not be glued in place again.

Watch out before how the ribs are mounted there is and out- and inside.

So the only thing that is needed is a way to seperate the subplatter from the alumium platter…maybe hot water woul help, I don´t know.

I wish you good luck!

Kind regards

Christian

26 September 2022 at 11:35 #39266actually got it back together. And it’s not bad. I could have done better but pretty happy with it. thanks for the help. Now to adjust the height

27 September 2022 at 01:47 #39270Hi

Didn’t heard about a special antistatic coating, indeed the original coating is very fragile, never use rough cleaning tools like scotch sponges .

I’ve used a thin layer 2 K clear coat wich is more resistant against scratches and touching.

Had never any problems with static on vinyl.

Regards

Christian

27 September 2022 at 02:21 #39267one question. How did you raise up the platter to be level with the surrounds? the brass screw/nut won’t go high enough. Did you add some shims underneath the platter?

thx

27 September 2022 at 03:24 #39271Plastic lacquer?

I would imagine that could cause static problems.Martin

27 September 2022 at 05:44 #39272Just putting it together. Thanks for the advice. I’ll let you know if there are any static problems

27 September 2022 at 07:22 #39268- As you removed the ribs the platter will loose,about 1 to 2 mm height.

- Tage some ( maybe 6 around the outer edge of the subplatter) felt pads to raise to desired heisst.

27 September 2022 at 11:35 #39269Wasn’t it something about antistatic coating that was very fragile and shall not be removed?

Did you experience anything about that after your works?

Thank you.

- AuthorPosts

- You must be logged in to reply to this topic.