- This topic has 5 replies, 2 voices, and was last updated 2 years, 6 months ago by

matador.

- AuthorPosts

- 29 July 2022 at 07:40 #36430

Hi alls,

I had this 1203 lying around for a long time. It was working well but too slow so I jumped in the bath of the re-infusing attempt. It looks like it worked (process documented below) but after reassembly, the deck needs to click on the lift button to start to spin. First click, the platter spin just a little (like 20°) and stop, Second click the deck works as expected. I’ve lubricated the center cam wheel, maybe I shouldn’t have? Other thing I touched was taking out the motor and back again. The speed selector do lift the idler wheel as it should. Any idea?

Thank you.

29 July 2022 at 08:14 #36431I’ve lubricated the center cam wheel, maybe I shouldn’t have?

You shouldn’t.

These cams MUST run dry and clean.Martin

29 July 2022 at 08:30 #36432While waiting for help, I thought someone may be interested in the re-infusing process I used, since it is well explain all over the internet but not often from a beginner point of view.

Disclamer: I know it could have been made better, with better oil, better vacuum device, better skills. But before investing too much, I thought I might give a quick test ride through the full process without any error that can’t be adresse with a little acetone bath.

First step was to take out and dismantle the motor. I decided to take out the full motor assembly before taking it appart. It was in bad shape, rusty, dirty. The rotor itself had rust marks, like drops of liquid that dried on it. I cleaned it and the inner side of the stator, with alcohol.

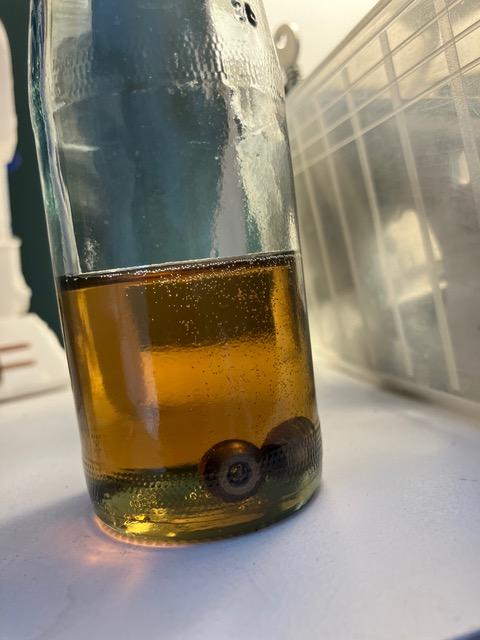

I finally made it to the pearls. Beware, the two pearls are different: one (the bottom one) is a ball, the other (the spindle side one) has a little cylinder part like a jar. Be sure to take pictures at every step.

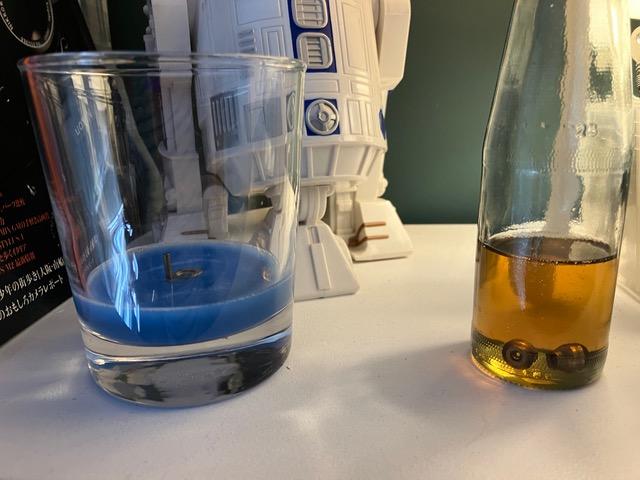

I thoroughly cleaned the pearls with acetone and let them bath for several hours.

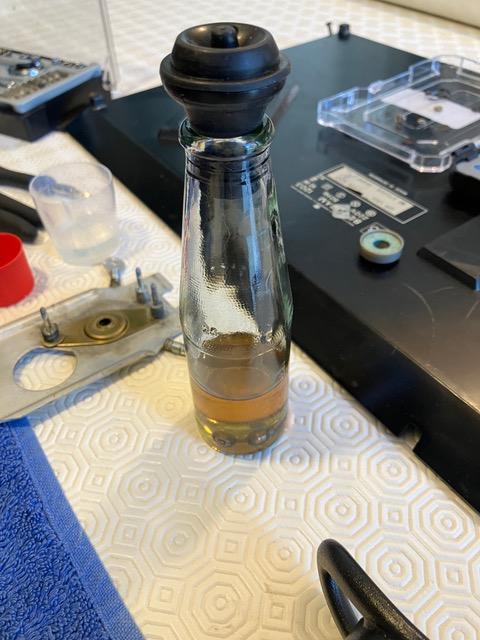

To do the vacuum I used a wine pump and a little bottle. I thought that the smaller the bottle the stronger the vacuum. For the oil I used the first SAE30 I could find: 4 strokes for lawnmower, it come in little container. Put the oil in the bottle, carefully drop the balls (I’ve read they break easily), close the bottle with the special thingy and start to pump.

After few seconds, bubbles starts to form around the pearls.

I pumped a little more from time to time all along the day.

In the meantime, I read somewhere something I thought couldn’t be armful.

So I soaked the idler wheel in fabric softener. for like 10 hours.

The balls kept bubbling all night long…

With some magic!

The next day I put it all back together. The deck spins a right speed and silently (it was not so noisy before).

Hope this helps.

29 July 2022 at 08:32 #36433You shouldn’t. These cams MUST run dry and clean. Martin

Thank you Martin,

I felt like I did something wrong. I good to clean it all.

Can this be the cause of the double click problem?30 July 2022 at 10:08 #36434The cam and cogs have all been carefully cleaned.

Still need two clicks 🙁30 July 2022 at 11:12 #36435Further investigations: it seems to be mechanical.

The hooked lever that pushes into the switch doesn’t engage enough at first LIFT button actuation to click in place and keep the platter running. At second actuation it fully clicks in and the starting process goes as it has to.I’ve cleaned it again but I wonder if it’s not related with the rod pushing that lever from the LIFT switch. But I see no adjustment and that rod looks so fragile…

Any idea please ?

- AuthorPosts

- You must be logged in to reply to this topic.