- This topic has 12 replies, 2 voices, and was last updated 1 year, 5 months ago by

Dillen.

- AuthorPosts

- 11 September 2023 at 11:06 #48868

Hello all,

I’m looking for help in getting my Beocord back to full health so I can enjoy my tapes to the full.

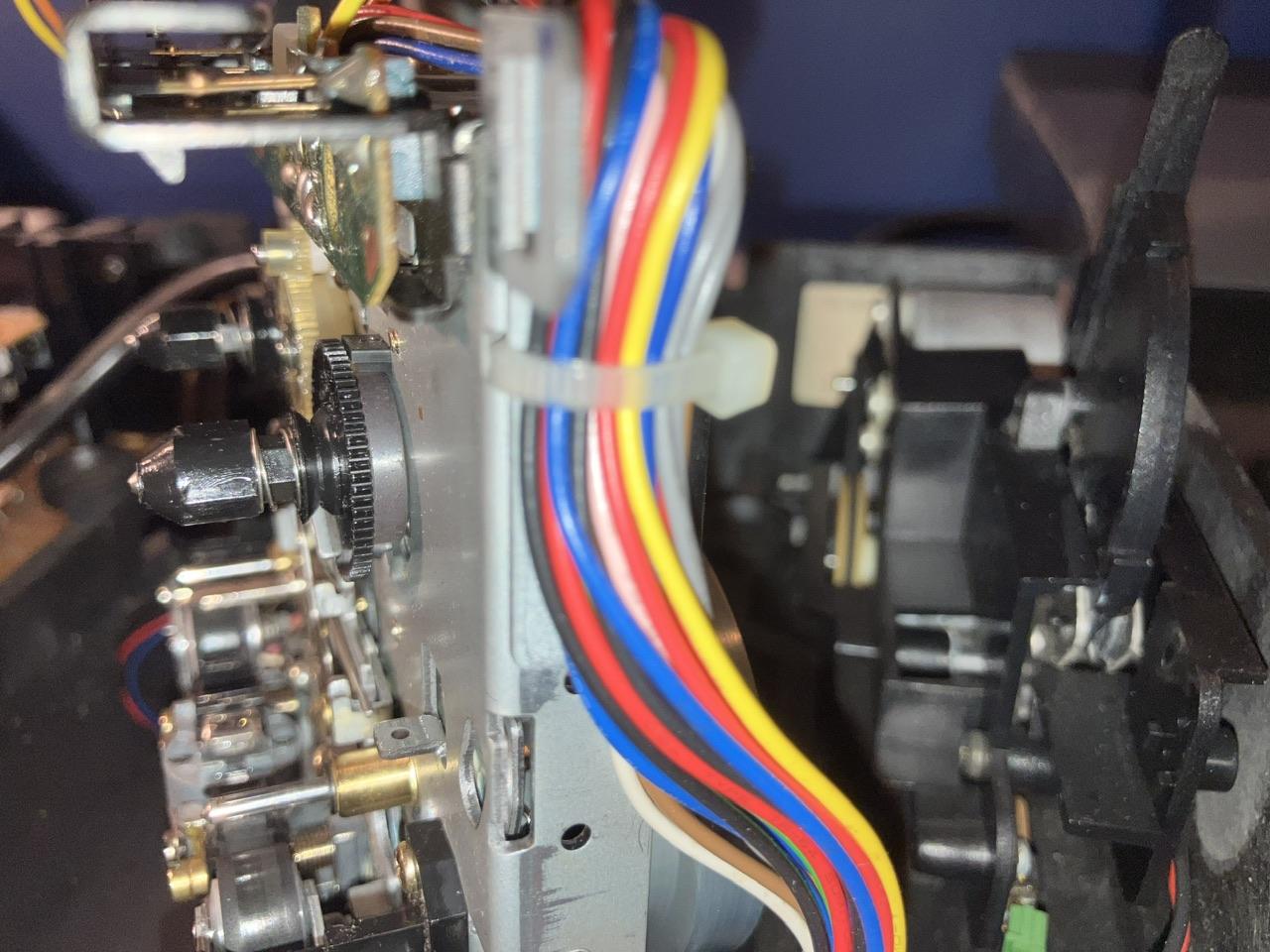

I have some video of my problem and some still photos too.The issue concerns the wind mechanism – sometimes the tape will auto-reverse randomly. Sometimes it just stops. Rewind and fast forward sometimes work, sometimes don’t. In each instance the tape is not tight.

I have the single belt version with the slower, smoother action. I fitted a new belt recently. Both large metal wheels are clean as are the two smaller plastic wheels.

Can anyone tell me what might be causing the issues in the attached video?

Kind regards, Julian.

12 September 2023 at 02:31 #48869In order to check:

Bad tape.

Seized reel table. Take apart, clean and relubricate.

Problem with reel table brake.Martin

13 September 2023 at 02:49 #48870In order to check: Bad tape. Seized reel table. Take apart, clean and relubricate. Problem with reel table brake. Martin

Hi Martin, thank you for the pointers. I’ll check the ‘reel table’, once I find out what this is precisely. Is this the plane upon which the idler control wheels make contact to create drive?

The tapes appear to be good. They play well in other decks.Julian

13 September 2023 at 05:36 #48871The reel tables carry the spindles with tridents that grips into the spools with the tape.

Martin

13 September 2023 at 08:31 #48872The reel tables carry the spindles with tridents that grips into the spools with the tape.

Martin

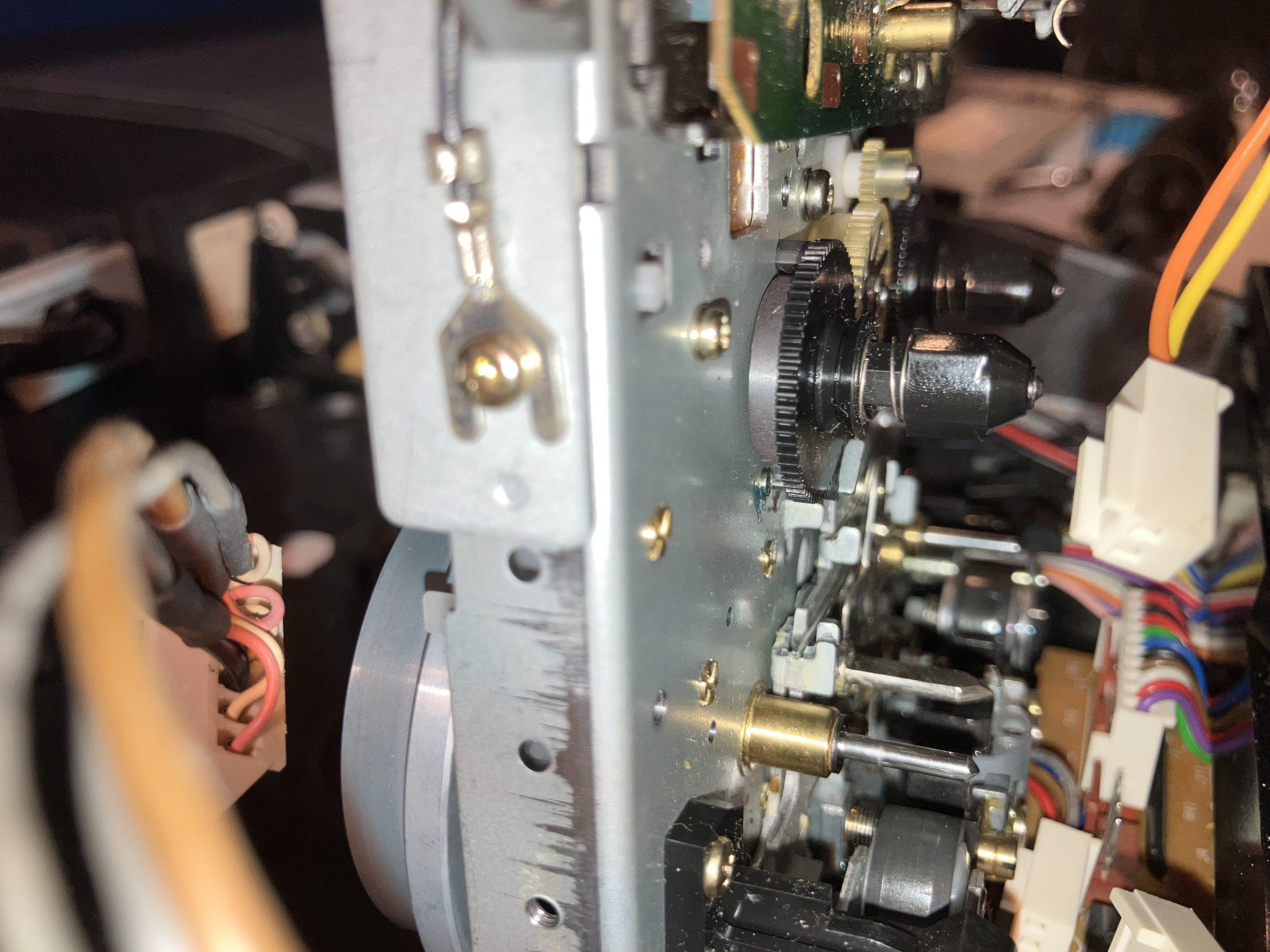

Hi again. Cool thank you for that – I feel certain you’re correct. I just checked both sides: the take-up reel is stiff and the reel table appears to be dragging on the mounting plate.

The supply reel moves a lot more freely and is looks to be sitting almost 1mm away from the mounting plate.

Photos below.So how can I release the position of the take-up reel table so it isn’t in contact with the mounting plate?

This is a mega challenge 🙂

13 September 2023 at 08:35 #48873

13 September 2023 at 08:35 #48873The reel tables carry the spindles with tridents that grips into the spools with the tape.

Martin

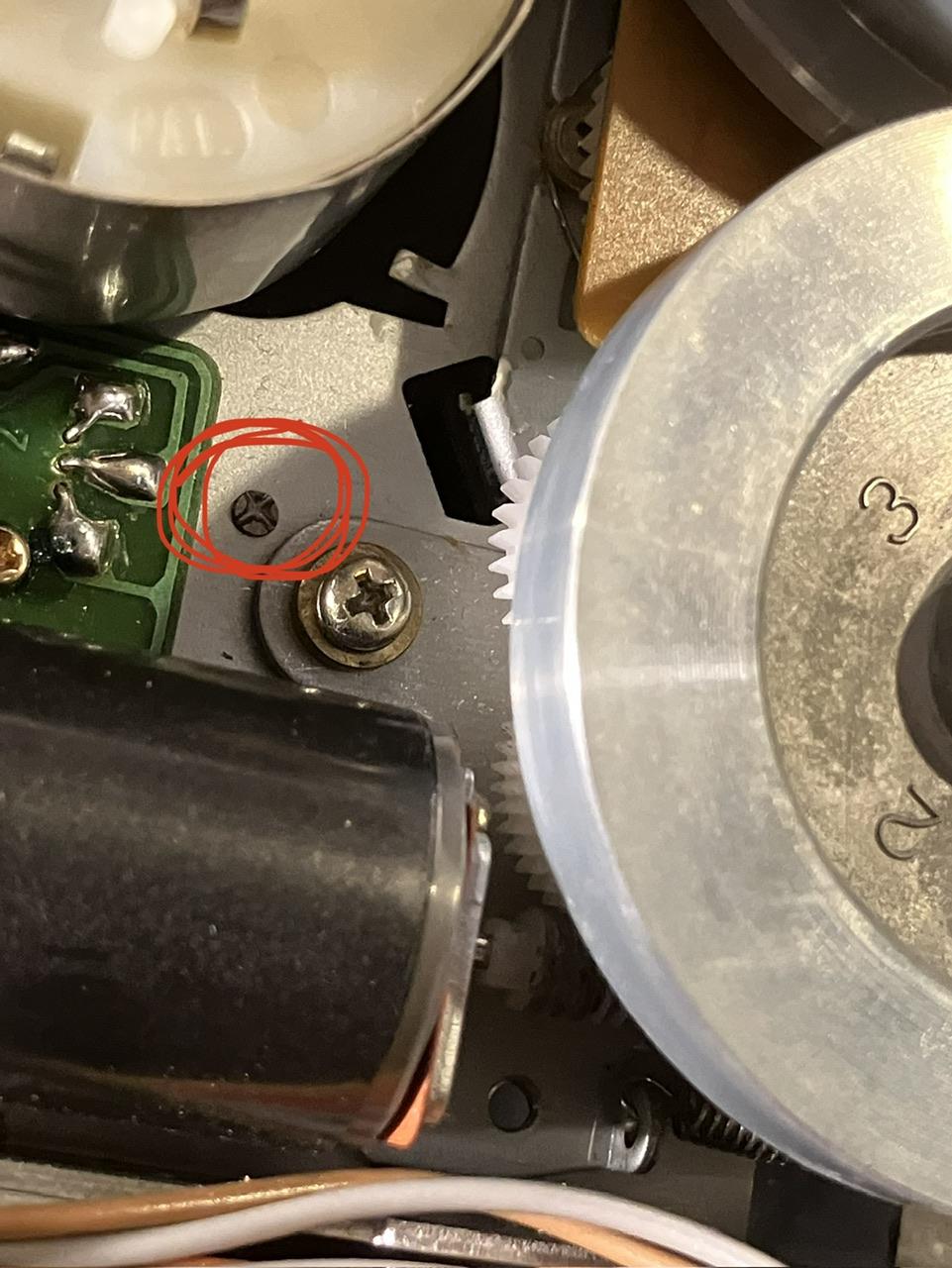

Here is a photo of the rear of the mechanism. It shows a very small almost cross-headed screw (v small) which appears to be the spindle on which the take-up reel table is set into the mounting plate with.

I feel quite sure I should not be attempting to adjust that!

13 September 2023 at 08:42 #48874

13 September 2023 at 08:42 #48874The reel tables carry the spindles with tridents that grips into the spools with the tape.

Martin

Actually on even closer inspection the reel table, as I understand it, appears to have become seperated from the plastic gear wheel just beneath the spring and the trident. Perhaps I can gently prize the reel table off the mounting plate and squeeze it and the plastic gear wheel together?

Julian

13 September 2023 at 10:01 #48875

13 September 2023 at 10:01 #48875Yes, the magnet has come lose.

You must take off the the reel table and glue the magnet back onto it.Martin

15 September 2023 at 11:57 #48876Yes, the magnet has come lose.

You must take off the the reel table and glue the magnet back onto it.Martin

Aha! Thank you. I shall endeavour to do just that. Having checked under the manuals section I can’t see instructions on how to safely dismantle this assembly.

I’ll check on the Tapeheads forum but you may find me back here again asking for more help.Have a cool weekend!

Julian

16 September 2023 at 03:19 #48878Carefully remove the locking washer on the top of the spool. It has a slit so is usually not difficult to remove.

Then take off the spool – note the small anti-vibration insert. It’s a tiny round bronze plate, wedged up against the spindle – easily lost.

While in there, I suggest you clean the spindle and inside of the spool off old grease and add a small amount of fresh white lithium grease.Martin

Thank you so much Martin! I followed your instructions and everything now works beautifully!

Those little copper discs really are quite delicate and without your advice I would no doubt have lost them.

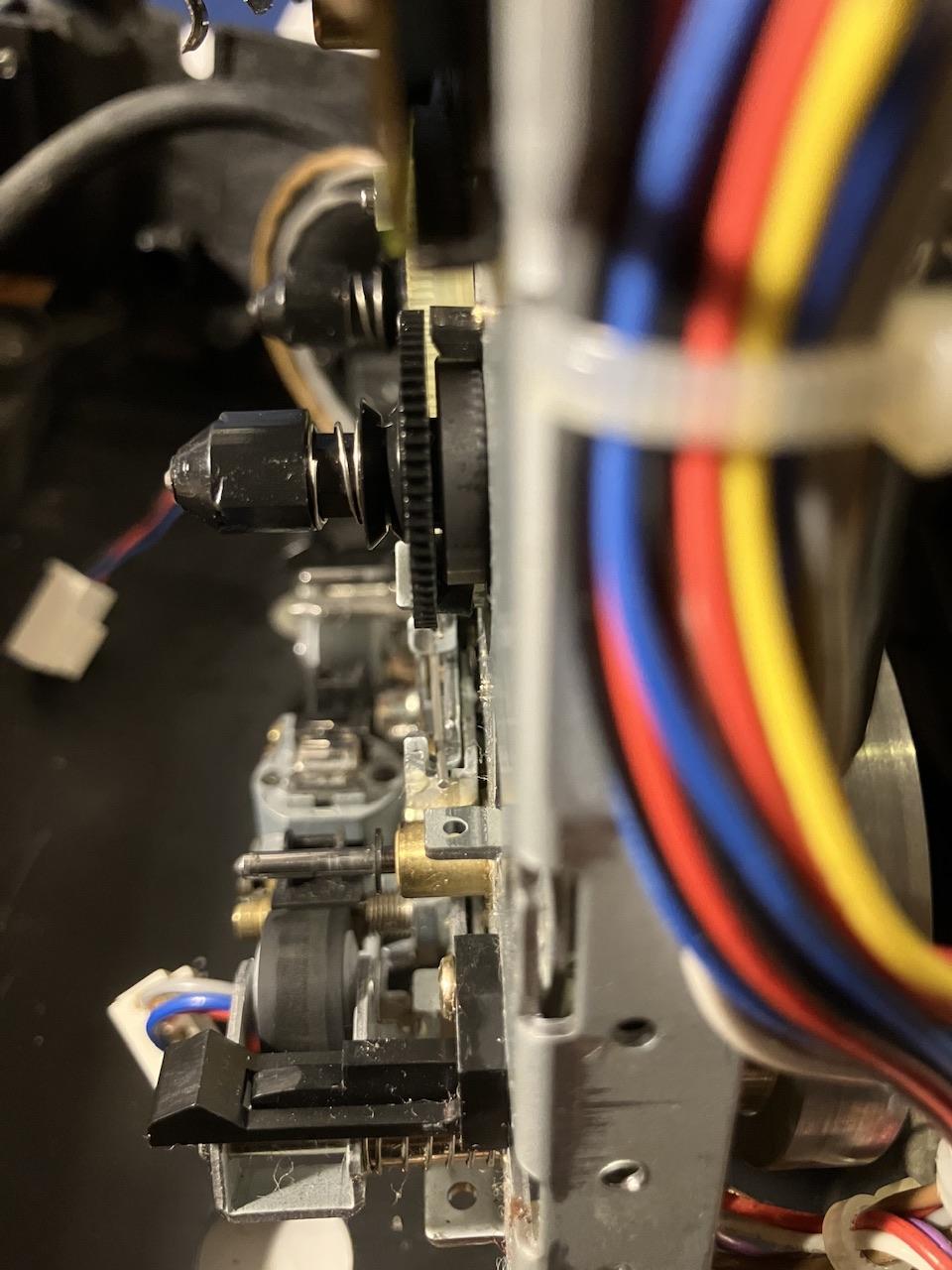

Beoworld saves the day again!The photos show the spindle after the split washer, trident thingy, spring and spool had been removed. It was very dirty and received a good clean with isopropanol. I lubricated it with a silicon spray applied carefully with a cotton tip – my town doesn’t stock white lithium grease so I may have to go back and redo the lubricating.

Another photo shows all the little parts – however at this point I didn’t know that the little copper anti-vibration plate was concealed inside the spool. I was lucky not to misplace it.

The other photos are of what caused my Beocord to stop winding tape. The donut-shaped magnet had indeed come away from the spool. It needed cleaning and re-glueing. I chose a gel superglue and applied it sparingly to the spool. Once seated I drank a tea then got to work cleaning up the transport. I went over the capstans and pinch rollers again and wiped Isopropanol over the large drive wheels. They were clean but I thought I may as well clean everything I could get to. I also cleaned and relubricated the worm drive which I think controls the auto reverse action.

This Beocord is now back to good health and will keep the tapes rolling for a good long time 🙂

Julian

16 September 2023 at 03:25 #48879Final photo of the Beocord reunited with its siblings and pumping out a bit of Prodigy 😀

16 September 2023 at 05:41 #48880Good job!

Martin

16 September 2023 at 07:35 #48877Carefully remove the locking washer on the top of the spool. It has a slit so is usually not difficult to remove.

Then take off the spool – note the small anti-vibration insert. It’s a tiny round bronze plate, wedged up against the spindle – easily lost.

While in there, I suggest you clean the spindle and inside of the spool off old grease and add a small amount of fresh white lithium grease.Martin

- AuthorPosts

- You must be logged in to reply to this topic.